Abstract

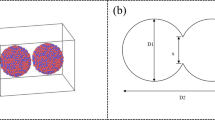

This paper presents an atomistic scale model on sintering of nickel particles in direct metal laser sintering process. Both sintering phenomena and mechanical strength of sintered particles are simulated using molecular dynamics method. A two-particle atomistic model is developed to investigate the diffusion of atoms during nickel sintering. The diffusion of particle surface is higher than the particle core, with calculated activation energy of nickel particle diffusion 6.10 kJ/mol in the particle core, and 6.24 kJ/mol on the particle surface, which are reasonably in agreement with the experimental data of 7.89 kJ/mol. The sintered model shows a 5-fold twinning structure at 1200 K, and two parallel twin boundaries at 1300 K. The mechanical properties of nickel nanoparticles sintered at various heating rates are investigated using uniaxial tensile test simulations. The results show that higher heating rate during sintering increases the mechanical strength of the sintered material. Deformation mechanism of sintered structures is illustrated from the correlation between stress and dislocation evolution.

Similar content being viewed by others

References

Wikipedia. Direct metal laser sintering. Available from: http://en.wikipedia.org/wiki/Direct_metal_laser_sintering (accessed May 7, 2016).

Wikipedia. Inconel. Available from: http://en.wikipedia.org/wiki/Inconel (accessed May 7, 2016).

J. Xu, R. Sakanoi, Y. Higuchi, N. Ozawa, K. Sato, T. Hashida, and M. Kubo: Molecular dynamics simulation of Ni nanoparticles sintering process in Ni/YSZ multi-nanoparticle system. J. Phys. Chem. C 117(19), 9663–9672 (2013).

L. Yang: Molecular Dynamics Simulation of Nanosintering Processes (University of Missouri, Columbia, 2010).

B. Cheng and A.H.W. Ngan: The sintering and densification behaviour of many copper nanoparticles: A molecular dynamics study. Comput. Mater. Sci. 74, 1–11 (2013).

B. Cheng and A.H.W. Ngan: Thermally induced solid-solid structural transition of copper nanoparticles through direct geometrical conversion. J. Chem. Phys. 138(16), 164314 (2013).

B.J. Henz, T. Hawa, and M. Zachariah: Molecular dynamics simulation of the kinetic sintering of Ni and Al nanoparticles. Mol. Simul. 35(10–11), 804–811 (2009).

Y. Zhang, L. Wu, H. El-Mounayri, K. Brand, and J. Zhang: Molecular dynamics study of the strength of laser sintered iron nanoparticles. Procedia Manufacturing 1, 296–307 (2015).

S. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117(1), 1–19 (1995).

G. Bonny, R.C. Pasianot, and L. Malerba: Fe–Ni many-body potential for metallurgical applications. Modell. Simul. Mater. Sci. Eng. 17(2), 025010 (2009).

M.S. Daw and M.I. Baskes: Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B: Condens. Matter Mater. Phys. 29(12), 6443–6453 (1984).

R.L. Coble: Sintering crystalline solids. I. Intermediate and final state diffusion models. J. Appl. Phys. 32(5), 787–792 (1961).

H. Pan, S.H. Ko, and C.P. Grigoropoulos: The solid-state neck growth mechanisms in low energy laser sintering of gold nanoparticles: A molecular dynamics simulation study. J. Heat Transfer 130(9), 092404–092404 (2008).

LAMMPS, http://www.cs.sandia.gov/∼sjplimp/lammps.html (accessed May 7, 2016).

R.M. German and Z.A. Munir: Surface area reduction during isothermal sintering. J. Am. Ceram. Soc. 59(9–10), 379–383 (1976).

A.G. Elliot and Z.A. Munir: The sintering of nickel/aluminium spheres to nickel plates. J. Mater. Sci. 3(2), 150–157 (1968).

B. Qian, L. Taimisto, A. Lehti, H. Piili, O. Nyrhilä, A. Salminen, and Z. Shen: Monitoring of temperature profiles and surface morphologies during laser sintering of alumina ceramics. J. Asian Ceram. Soc. 2(2), 123–131 (2014).

A. Moitra, S. Kim, S.-G. Kim, S.J. Park, R.M. German, and M.F. Horstemeyer: Investigation on sintering mechanism of nanoscale tungsten powder based on atomistic simulation. Acta Mater. 58(11), 3939–3951 (2010).

R.M. German: Chapter Seven—Thermodynamic, and kinetic treatments. In Sintering: from Empirical Observations to Scientific Principles (Butterworth-Heinemann, Boston, 2014); pp. 183–226.

B. Cheng and A.H.W. Ngan: The crystal structures of sintered copper nanoparticles: A molecular dynamics study. Int. J. Plast. 47, 65–79 (2013).

B. Cheng and A.H.W. Ngan: Crystal plasticity of Cu nanocrystals during collision. Mater. Sci. Eng., A 585, 326–334 (2013).

S. Alexander and A. Karsten: Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Modell. Simul. Mater. Sci. Eng. 18(8), 085001 (2010).

Wikipedia. Nickel. Available from: http://en.wikipedia.org/wiki/Nickel (accessed May 7, 2016).

ACKNOWLEDGMENT

J.Z. acknowledges Walmart Foundation’s support of research project “Optimal Plastic Injection Molding Tooling Design and Production through Advanced Additive Manufacturing”. We also thank the critical comments by the anonymous reviewer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Zhang, J. Sintering phenomena and mechanical strength of nickel based materials in direct metal laser sintering process—a molecular dynamics study. Journal of Materials Research 31, 2233–2243 (2016). https://doi.org/10.1557/jmr.2016.230

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.230