Abstract

This paper critically evaluates methods used to synthesize boride compounds with emphasis on diborides of the early transition metals. The earliest reports of the synthesis of boride ceramics used impure elemental powders to produce multiphase reaction products; phase-pure borides were only synthesized after processes were established to purify elemental boron. Carbothermal reduction of the corresponding transition metal oxides emerged as a viable production route and continues to be the primary method for the synthesis of commercial transition metal diboride powders. Even though reaction-based processes and chemical synthesis methods are mainly used for research studies, they are powerful tools for producing diborides because they provide the ability to tailor purity and particle size. The choice of synthesis method requires balancing factors that include cost, purity, and particle size with the performance needed in expected applications.

Similar content being viewed by others

References

Unless otherwise noted, melting temperatures are from Alloy Phase Diagrams: ASM Handbook, Vol. 3 (ASM International, Materials Park, OH, 1992).

All data on space groups were taken from the PDF-2 Database (International Centre for Diffraction Data, Newtown Square, PA).

S. Madtha, C. Lee, and K.S. Ravi Chandran: Physical and mechanical properties of nanostructured titanium boride (TiB) ceramic. J. Am. Ceram. Soc. 91, 1319 (2008).

L. Sun, Y. Gao, B. Xiao, Y. Li, and G. Wang: Anisotropic elastic and thermal properties of titanium borides by first principles calculations. J. Alloys Compd. 579, 457 (2013).

K.B. Panda and K.S. Ravi Chandran: First principles determination of elastic constants and chemical bonding of titanium boride (TiB) on the basis of density functional theory. Acta Mater. 54, 1641 (2006).

A.L. Chamberlain, W.G. Fahrenholtz, G.E. Hilmas, and D.T. Ellerby: High strength ZrB2-based ceramics. J. Am. Ceram. Soc. 87, 1170 (2004).

N.L. Okamoto, M. Kusakari, K. Tanaka, H. Inui, and S. Otani: Anisotropic elastic constants and thermal expansivities in monocrystal CrB2, TiB2, and ZrB2. Acta Mater. 58, 76 (2010).

P. Rogl and P.E. Potter: A critical review and thermodynamic calculation of the binary system: Hafnium–boron. CALPHAD 12, 207 (1988).

E. Rudy: Ternary Phase Equilibria in Transition Metal–Boron–Carbon–Silicon Systems: Part V. Compendium of Phase Diagram Data. Technical Report Number AFML-TR-65-2 (Air Force Materials Laboratory, Wright-Patterson Air Force Base, May 1969).

K. Sairam, J.K. Sonber, T.S.R.Ch. Murthy, C. Subramanian, R.K. Fortedar, and R.C. Hubi: Reaction spark plasma sintering of niobium diboride. Int. J. Refract. Met. Hard Mater. 43, 259 (2014).

M. Zhang, H. Wang, H. Wang, T. Cui, and Y. Ma: Structural modifications and mechanical properties of molybdenum borides from first principles. J. Phys. Chem. C 114, 6722 (2010).

H-H. Chen, Y. Bi, Y. Cheng, G. Ji, and L. Cai: Elastic stability and electronic structure of tantalum boride investigated via first-principles density functional calculations. J. Phys. Chem. Solids 73, 1197 (2012).

X. Zhang, G.E. Hilmas, and W.G. Fahrenholtz: Synthesis, densification, and mechanical properties of TaB2. Mater. Lett. 62, 4251 (2008).

W.J. Zhao and Y.X. Wang: Structural, mechanical, and electronic properties of TaB2, TaB, IrB2, and IrB: First principles calculations. J. Solid State Chem. 182, 2880 (2009).

H. Duschanek and P. Rogl: Critical assessment and thermodynamic calculation of the binary system boron-tungsten. J. Phase Equilib. 16, 150 (1995).

Y. Chen, D. He, J. Qin, Z. Kou, S. Wang, and J. Wang: Ultrahigh-pressure densification of nanocrystalline WB ceramics. J. Mater. Res. 25, 637 (2010).

E. Zhao, J. Meng, Y. Ma, and Z. Wu: Phase stability and mechanical properties of tungsten borides from first principles calculations. Phys. Chem. Chem. Phys. 12, 13158 (2010).

H. Guo, Z. Li, J. Zhang, H. Niu, F. Gao, R.E. Ewing, and J. Lian: Origin of the rigidity in tetragonal MB (M = Cr, Mo, and W) and softening of defective WB: First principles investigations. Comput. Mater. Sci. 53, 460 (2012).

J. Qin, D. He, J. Wang, L. Fang, Y. Li, J. Hu, Z. Kou, and Y. Bi: Is rhenium diboride a superhard material? Adv. Mater. 20, 4780 (2008).

M. Hebbache, L. Suparevic, and D. Zivkovic: A new superhard material: Osmium diboride OsB2. Solid State Commun. 139, 227 (2006).

H-Y. Chung, Y-M. Yang, S.H. Tolbert, and R.B. Kaner: Anisotropic mechanical properties of ultra-incompressible hard osmium diboride. J. Mater. Res. 23, 1797 (2008).

A.L. Ivanovskii: Mechanical, and electronic properties of diborides of transition 3d–5d metals from first principles: Toward search of novel ultra-incompressible and superhard materials. Progr. Mater. Sci. 57, 184 (2012).

Y. Zhou, J. Wang, Z. Li, X. Sun, and J. Wang: First-principles investigation on anisotropic chemical bonding and elastic properties of transition metal diborides TMB2 (TM = Zr, Hf, Nb, Ta, and Y). In Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications, W.G. Fahrenholtz, E.J. Wuchina, W.E. Lee, and Y. Zhou eds.; Wiley: New York, 2014; pp. 60–82.

A.L. Ivanovskii, I.R. Shein, and N.I. Medvedeva: Non-stoichiometric s-, p-, and d-metal diborides: Synthesis, properties, and simulation. Russ. Chem. Rev. 77, 467 (2008).

P. Vajeeston, P. Ravindran, C. Ravi, and R. Asokamani: Electronic structure, bonding, and ground-state properties of AlB2-type transition-metal diborides. Phys. Rev. B: Condens. Matter Mater. Phys. 63, 045115–1 (2001).

G. Harrington, G.E. Hilmas, and W.G. Fahrenholtz: Effect of carbon on the thermal and electrical transport properties of zirconium diboride. J. Eur. Ceram. Soc. 35, 887 (2015).

S. Guo, T. Nishimura, and Y. Kagawa: Preparation of zirconium diboride ceramics by reactive spark plasma sintering of zirconium hydride-boron powders. Scr. Mater. 65, 1018 (2001).

J.M. Lonergan, W.G. Fahrenholtz, and G.E. Hilmas: Zirconium diboride with high thermal conductivity. J. Am. Ceram. Soc. 97, 1689 (2014).

L. Zhang, D.A. Pejaković, J. Marschall, and M. Gasch: Thermal and electrical transport properties of spark plasma-sintered HfB2 and ZrB2 ceramics. J. Am. Ceram. Soc. 94, 2562 (2011).

R.A. Andrievski: Superhard materials based on nanostructured high-melting point compounds: Achievements and perspectives. Int. J. Refract. Met. Hard Mater. 19, 447 (2001).

B. Basu, G.B. Raju, and A.K. Suri: Processing and properties of monolithic TiB2-based materials. Int. Mater. Rev. 51, 352 (2006).

X. Zhang, X. Luo, J. Han, J. Li, and W. Han: Electronic structure, elasticity, and hardness of diborides of zirconium and hafnium: First principles calculations. Comput. Mater. Sci. 4, 411 (2008).

J.W. Lawson, C.W. Bauschlicher, Jr., and M.S. Daw: Ab-initio computations of electronic, mechanical, and thermal properties of ZrB2 and HfB2. J. Am. Ceram. Soc. 94, 3494 (2011).

S.Q. Guo: Densification of ZrB2-based composites and their mechanical and physical properties: A review. J. Eur. Ceram. Soc. 29, 995 (2009).

E. Wuchina, M. Opeka, S. Causey, K. Buesking, J. Spain, A. Cull, J. Routbort, and F. Guitierrez-Mora: Designing of ultrahigh-temperature applications: The mechanical and thermal properties of HfB2, HfCx, HfNx, and αHf(N). J. Mater. Sci. 39, 5939 (2004).

P. Kolodziej, J. Salute, and D.L. Keese: First Flight Demonstration of a Sharp Ultra-High Temperature Ceramic Nosetip. NASA Technical Report TM-112215 (December 1997).

E.L. Courtright, H.C. Graham, A.P. Katz, and R.J. Kerans: Ultra-High Temperature Assessment Study–Ceramic Matrix Composites. Final Report WL-TR-91-4061 (Wright Laboratory Materials Directorate, Wright Patterson Air Force Base, Dayton, OH, September 1992).

D.M. Van Wie, D.G. Drewry, Jr., D.E. King, and C.M. Hudson: The hypersonic environment: Required operating conditions and design challenges. J. Mater. Sci. 39, 5915 (2004).

T.A. Jackson, D.R. Eklund, and A.J. Fink: High speed propulsion: Performance advantage of advanced materials. J. Mater. Sci. 39, 5905 (2004).

K-I. Takagi: Development and application of high strength ternary boride base cermets. J. Solid State Chem. 179, 2809 (2006).

B. Yuan, G-J. Zhang, Y-M. Kan, and P-L. Wang: Reactive synthesis and mechanical properties of Mo2NiB2 based hard alloy. Int. J. Refract. Met. Hard Mater. 28, 291 (2010).

G.B. Raju and B. Basu: Development of high temperature TiB2-based ceramics. Key Eng. Mater. 395, 894 (2009).

B.R. Golla, T. Bhandari, A. Mukopadhyay, and B. Basu: Titanium diboride. In Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications, W.G. Fahrenholtz, E. Wuchina, W.E. Lee, and Y. Zhou eds.; Wiley-Blackwell: New York, 2015; pp. 316–360.

A.K. Suri, N. Krishnamurthy, and I.S. Batra: Materials issues in fusion reactors. In Journal of Physics: Conference Series, 208, Paper Number 012001, 2010.

H.F. Jackson, D.D. Jayaseelan, W.E. Lee, M.J. Reese, F. Inam, D. Manara, C.P. Casoni, F. De Bruycker, and K. Boboridis: Laser melting of spark plasma-sinered zirconium carbide: Thermophysical properties of a generation IV very high-temperature reactor material. Int. J. Appl. Ceram. Technol. 7, 316 (2010).

J. She, Y. Zhan, M. Pang, C. Li, and W. Yang: In-situ synthesized (ZrB2 + ZrC) hybrid short fibers reinforced Zr matrix composites for nuclear applications. Int. J. Refract. Met. Hard Mater. 29, 401 (2011).

E. Wuchina, E. Opila, M. Opeka, W. Fahrenholtz, and I. Talmy: UHTCs: Ultra-high temperature ceramic materials for extreme environment application. Interface, 16, 30 (2007).

M.M. Opeka, I.G. Talmy, and J.A. Zaykoski: Oxidation-based materials selection for 2000 °C+ hypersonic aerosurfaces: Theoretical considerations and historical experience. J. Mater. Sci. 39, 5887 (2004).

T.H. Squire and J. Marschall: Material property requirements for analysis and design of UHTC components in hypersonic applications. J. Eur. Ceram. Soc. 30, 2239 (2010).

M.J. Gasch, D.T. Ellerby, and S.M. Johnson: Ultra-high temperature ceramic composites. In Handbook of Ceramic Composites, N.P. Bansal ed.; Kluwer Academic Publishers: Boston, 2005; pp. 197–224.

R. Telle, L.S. Sigl, and K. Takagi: Boride-based hard materials. In Handbook of Ceramic Hard Materials, R. Riedel ed.; Wiley-VCH: Weinheim, Germany, 2000; pp. 802–945.

P.H. Mayrhofer, C. Mitterer, L. Hultman, and H. Clemens: Microstructural design of hard coatings. Prog. Mater. Sci. 51, 1032 (2006).

Z. Xie, T. Zhou, and Y. Gou: Synthesis and characterization of zirconium diboride ceramic precursor. Ceram. Int. 41, 6226 (2015).

G-J. Zhang, H-T. Liu, W-W. Wu, J. Zou, D-W. Ni, W-M. Guo, J-X. Liu, and X-G. Wang: Reactive processes for diboride-based ultra-high temperature ceramics. In Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications, W.G. Fahrenholtz, E. Wuchina, W.E. Lee, and Y. Zhou eds.; Wiley-Blackwell: New York, 2015; pp. 33–59.

H. Moissan: Nouvelles Reserches sur le Chrome. C. R. Séances 119, 185 (1894).

H. Moissan: Reserches sur le tungsten. C. R. Séances 123, 13 (1896).

H. Moissan: Préparation et Properiétès du Titane. C. R. Séances 120, 290 (1895).

S.A. Tucker and H.R. Moody: The preparation of a new metal boride. Proc. Chem. Soc., London 17, 129 (1901).

S.A. Tucker and H.R. Moody: The preparation of some new metal borides. J. Chem. Soc. 81, 14 (1902).

E. Wedekind: Synthese von Boriden im Elektrischen Vakuumofen. Ber. Dtsch. Chem. Ges. 46, 1198 (1913).

P.M. McKenna: Tantalum carbide: Its relation to other hard refractory compounds. Ind. Eng. Chem. 28, 767 (1936).

C. Agte and K. Moers: Methoden zur Reindarstellung hochschmelzender carbide, nitride und boride und Beschreibung einiger ihrer Eigenschaften. Zeitschrift für Anorganische und Allgemeine Chemie 198, 233 (1931).

D. Coster and G. Hervey: On the new element hafnium. Nature 111, 185 (1923).

R. Kiessling: A method for preparing boron of high purity. Acta Chem. Scand. 2, 707–712 (1948).

R. Kiessling: The borides of tantalum. Acta Chem. Scand. 3, 603 (1949).

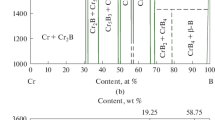

R. Kiessling: The binary system chromium–boron. Acta Chem. Scand. 3, 595 (1949).

R. Kiessling: The crystal structures of molybdenum and tungsten borides. Acta Chem. Scand. 1, 893 (1947).

R. Kiessling: The binary system zirconium–boron. Acta Chem. Scand. 3, 90 (1949).

P. Peshev, G. Bliznakov, and L. Leyarovska: On the preparation of some chromium, molybdenum, and tungsten borides. J. Less-Common Met. 13, 241 (1967).

P. Peshev and G. Bliznakov: On the borothermic preparation of titanium, ziroconium, and hafnium borides. J. Less-Common Met. 14, 23 (1967).

P. Peshev, L. Leyarovska, and G. Bliznakov: On the borothermic preparation of some vanadium, niobium, and tantalum borides. J. Less-Common Met. 15, 259 (1968).

G. Bliznakov and P. Peshev: A thermodynamic study of the reactions in the chemical transport of boron. J. Less-Common Met. 47, 61 (1976).

Y.B. Kuz’ma, T.I. Serebryakova, and A.M. Plakhina: Polymorphic transformations of W2B5. Zh. Neorg. Khim. 12, 559 (1968).

J.A. Nelson, T.A. Willmore, and R.C. Womeldorph: Refractory bodies composed of boron and titanium carbides bonded with metals. J. Electrochem. Soc. 98, 465 (1951).

G.A. Meerson, G.V. Samsonov, R.B. Kotel’nikov, and N.Y. Tsitina: Vacuum thermal production of borides of refractory metals and investigation of several boride systems. Sbornik Nauch Trudov Moskov. Univ. Tsvetnykh Metal. I Zolota 25, 209 (1955).

R. Meyer and H. Pastor: The borides of titanium and zirconium preparation, properties, and applications. Bull. Soc. Fr. Ceram. 66, 59 (1965).

R. Thompson: The chemistry of metal borides and related compounds. In Progress in Boron Chemistry, Vol. 2, R.J. Brotherson and H. Steinberg eds.; Permangon Press: Oxford, UK, 1970; pp. 173–230.

L.Ya. Markovskii and N.V. Verkshina: A magnesium thermic method for the preparation of metal borides. Zh. Prikl. Khim. 40, 1824 (1967).

J.L. Andrieux: Making metallic powders by electrolysis of fused salts. Rev. Metall. 45, 49 (1948).

J.T. Norton, H. Blumenthal, and S.J. Sindeband: Structure of diborides of titanium, zirconium, columbium, tantalum and vanadium. Met. Trans. 185, 749 (1949).

A. Roos: Boron derivatives, metallic borides, and their uses. Chim. Ind. 82, 339 (1959).

J.J. Gebhardt and R.F. Cree: Vapor-deposited borides of group IVA metals. J. Am. Ceram. Soc. 48, 262 (1965).

R.H. Valentine, T.F. Jambois, and J.L. Margrave: Thermodynamic properties of inorganic substances VII: The high temperature heat content of zirconium diboride. J. Chem. Eng. Data 9, 182 (1964).

D. Kalish and E.V. Clougherty: Densification mechanisms in high-pressure hot-pressing of HfB2. J. Am. Ceram. Soc. 52, 26 (1969).

D. Kalish, E.V. Clougherty, and K. Kreder: Strength, fracture mode, and thermal stress resistance of HfB2 and ZrB2. J. Am. Ceram. Soc. 52, 30 (1969).

E. Rudy, St. Windisch, and Y.A. Chang: Ternary Phase Equilibria in Transition Metal–Boron–Carbon–Silicon Systems: Part I. Related Binary Systems, Volume I. Mo–C System. Technical Report Number AFML-TR-65-2 (Air Force Materials Laboratory, Wright-Patterson Air Force Base, January 1965).

R. Naslain, J. Etourneau, and P. Hagenmuller: Alkali metal borides. In Boron and Refractory Borides, V.I. Markovich ed.; Springer-Verlag: Berlin, 1977; pp. 262–292.

R. Naslain, A. Guette, and P. Hagenmuller: Crystal chemistry of some boron-rich phases. J. Less-Common Met. 47, 1 (1976).

J. Etourneau, J.P. Mercurio, R. Naslain, and P. Hagenmuller: Comparative study of the thermal stability of some rare-earth borides. C. R. Seances Acad. Sci., Ser. C 274, 1688 (1972).

G.V. Samsonov and V.S. Nesphor: Alloys of rare metals with boron and silicon for some radio- and electrotechnical application. In Redkie Metally I Splavy, Trudy Pervogo Vseoyuz. Soveshchaniya po Splavam Redkikh Metal., Akad. Nauk S.S.S.R., Inst. Met. Im. A.A. Baikova, Moscow, 1957; p. 392.

P. Rogl and H. Nowotny: Structural chemistry of ternary metal borides: Rare earth metal-noble metal-boron. Rare Earths Mod. Sci. Technol. 2, 173 (1980).

P. Rogl and H. Nowotny: Structural chemistry of ternary metal borides. J. Less-Common Met. 61, 39 (1978).

R. Thomson: Production, fabrication, and uses of borides. In The Physics and Chemistry of Carbides, Nitrides and Borides, R. Freer ed.; Kluwer Academic Publishers: Dordrecht, 1990; pp. 113–120.

T. Lundström: Transition metal borides. In Boron and Refractory Borides, V.I. Markovich ed.; Springer-Verlag: Berlin, 1977; pp. 351–376.

C. Mroz: Zirconium diboride. Am. Ceram. Soc. Bull. 73, 141 (1994).

J.J. Kim and C.H. McMurtry: Titanium diboride powder production for engineered ceramics. Ceram. Eng. Sci. Proc. 6, 1313 (1985).

P. Schwarzkopf and R. Kieffer: Refractory Hard Metals: Borides, Carbides, Nitrides, and Silicides, Ch. 6: Zirconium carbide (The MacMillan Company, New York, 1953).

G.J.K. Harrington, J. Lonergan, W.G. Fahrenholtz, and G.E. Hilmas: Processing for improved thermal conductivity of zirconium diboride. In 12th International Conference on Ceramic Processing Science (ICCPS-12), Portland, OR, August 4–7, 2013.

Hafnium. In CRC Handbook of Chemistry and Physics, 62nd ed., R.C. Weast and M.J. Astle, eds. (CRC Press, Inc.: Boca Raton, 1983); p. B–19.

J.M. Lonergan, W.G. Fahrenholtz, and G.E. Hilmas: Thermal properties of Hf-Doped ZrB2 ceramics. J. Am. Ceram. Soc. 98, 2689 (2015).

H. Zhao, Y. He, and Z.Z. Jin: Preparation of zirconium diboride powder. J. Am. Ceram. Soc. 78, 2534 (1995).

S. Baik and P.F. Becher: Effect of oxygen contamination on densification of TiB2. J. Am. Ceram. Soc. 70, 527 (1987).

A.L. Chamberlain, W.G. Fahrenholtz, and G.E. Hilmas: Pressureless sintering of zirconium diboride. J. Am. Ceram. Soc. 89, 450 (2006).

S. Zhu, W.G. Fahrenholtz, G.E. Hilmas, and S.C. Zhang: Pressureless sintering of carbon-coated zirconium diboride powders. Mater. Sci. Eng., A 459, 167 (2007).

S.C. Zhang, G.E. Hilmas, and W.G. Fahrenholtz: Pressureless densification of zirconium diboride with boron carbide additions. J. Am. Ceram. Soc. 89, 1544 (2006).

W.G. Fahrenholtz, G.E. Hilmas, S.C. Zhang, and S. Zhu: Pressureless sintering of zirconium diboride: Particle size and additive effects. J. Am. Ceram. Soc. 91, 1398 (2008).

G. van de Goor, P. Sagesser, and K. Berroth: Electrically conductive ceramic composites. Solid State Ionics 101–103, 1163 (1997).

L.H. Li, H.E. Kim, and E.S. Kang: Sintering and mechanical properties of titanium diboride with aluminum nitride as a sintering aid. J. Eur. Ceram. Soc. 22, 973 (2002).

F. Monteverde and A. Bellosi: Beneficial effect of AlN as sintering aid on microstructure and mechanical properties of hot-pressed ZrB2. Adv. Eng. Mater. 5 (7) 508–512 (2003).

S. Zhu, W.G. Fahrenholtz, G.E. Hilmas, and S.C. Zhang: Pressureless sintering of zirconium diboride using boron carbide and carbon additions. J. Am. Ceram. Soc. 90, 3660 (2007).

D. Sciti, L. Silvestroni, V. Medri, and F. Monteverde: Sintering and densification mechanisms of ultra-high temperature ceramics. In Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications, W.G. Fahrenholtz, E.J. Wuchina, W.E. Lee, and Y. Zhou eds.; Wiley-Blackwell: New York, 2014; pp. 112–143.

W-M. Guo, Z-G. Yang, and G-J. Zhang: Synthesis of submicrometer HfB2 powder and its densification. Mater. Lett. 83, 52 (2012).

X-G. Wang, W-M. Guo, and G-J. Zhang: Pressureless sintering mechanism and microstructure of ZrB2–SiC ceramics doped with boron. Scr. Mater. 61, 177 (2009).

S. Ran, O. Van der Biest, and J. Vleugels: ZrB2 powders synthesis by borothermal reduction. J. Am. Ceram. Soc. 93, 1586 (2010).

J.K. Sonber, T.S.R.C. Murthy, C. Subramanian, S. Kumar, R.K. Fotedar, and A.K. Suri: Investigations on synthesis of ZrB2 and development of new composites with HfB2 and TiSi2. Int. J. Refract. Met. Hard Mater. 29, 21 (2011).

G.J. Zhang, Z.Y. Deng, N. Kondo, J.F. Yang, and T. Ohji: Reactive hot pressing of ZrB2–SiC composites. J. Am. Ceram. Soc. 83, 2330 (2000).

G.J. Zhang, M. Ando, J.F. Yang, T. Ohji, and S. Kanzaki: Boron carbide and nitride as reactants for in situ synthesis of boride-containing ceramic composites. J. Eur. Ceram. Soc. 24, 171 (2004).

J. Zou, J. Liu, G-J. Zhang, S. Huang, J. Vleugels, O. Van der Biest, and J.Z. Shen: Hexagonal BN-encapsulated ZrB2 particle by nitride boronizing. Acta Mater. 72, 167 (2014).

W.G. Fahrenholtz: Reactive processing in ceramic-based systems. Int. J. Appl. Ceram. Technol. 3, 1 (2006).

Y.M. Chiang, J.S. Haggerty, R.P. Messner, and C. Demetry: Reaction-based processing methods for ceramic-matrix. Am. Ceram. Soc. Bull. 68, 420 (1989).

A.L. Chamberlain, W.G. Fahrenholtz, and G.E. Hilmas: Reactive processing of zirconium diboride. J. Eur. Ceram. Soc. 29, 3401 (2009).

W-W. Wu, G-J. Zhang, and Y. Sakka: Nanocrystalline ZrB2 powders prepared by mechanical alloying. J. Asian Ceram. Soc. 1, 304 (2013).

D. Lee, J.J. Vlassak, and K. Zhao: First-principles theoretical studies and nanocalorimetry experiments on solid-state alloying of Zr–B. Nano Lett. 15, 6553 (2015).

A.L. Chamberlain, W.G. Fahrenholtz, and G.E. Hilmas: Low temperature densification of zirconium diboride ceramics by reactive hot pressing. J. Am. Ceram. Soc. 89, 3638 (2006).

C. Hu, J. Zou, Q. Huang, G. Zhang, S. Guo, and Y. Sakka: Synthesis of plate-like ZrB2 grains. J. Am. Ceram. Soc. 95, 85 (2012).

H.J. Jung, Y. Sohn, H.G. Sung, H.S. Hyun, and W.G. Shin: Physicochemical properties of ball milled boron particles: Dry versus wet ball milling process. Powder Technol. 269, 548 (2015).

W.G. Fahrenholtz: Reactive hot pressing of Al2O3–Ni composites. J. Mater. Sci. 38, 3073 (2003).

S. Guo, C. Hu, and Y. Kagawa: Mechanochemical processing of nanocrystalline zirconium diboride powder. J. Am. Ceram. Soc. 94, 3643 (2011).

S. Ran, O. Van der Biest, and J. Vleugels: ZrB2–SiC composites prepared by reactive pulsed electric current sintering. J. Euro. Ceram. Soc. 30, 2633 (2010).

S. Guo, D.H. Ping, and Y. Kagawa: Synthesis of zirconium diboride platelets from mechanically activated ZrCl4 and B powder mixture. Ceram. Int. 38, 5195 (2012).

I. Parkin: Solid state metathesis reaction for metal borides, silicides, pnictides and chalcogenides: Ionic or elemental pathways. Chem. Soc. Rev. 25, 199 (1996).

L. Rao, E.G. Gillan, and R.B. Kanera: Rapid synthesis of transition-metal borides by solid-state metathesis. J. Mater. Res. 10, 353 (1995).

E.G. Gillan and R.B. Kaner: Synthesis of refractory ceramics via rapid metathesis reactions between solid-state precursors. Chem. Mater. 8, 333 (1996).

R. Licheri, R. Orrù, C.A. Musa, and G. Cao: Combination of SHS and SPS techniques for fabrication of fully dense ZrB2–ZrC–SiC composites. Mater. Lett. 62, 432 (2008).

W-W. Wu, Z. Wang, G-J. Zhang, Y-M. Kan, and P-L. Wang: ZrB2 MoSi2 composites toughened by elongated ZrB2 grains via reactive hot pressing. Scr. Mater. 61, 316 (2009).

H-T. Liu, W-W. Wu, J. Zou, D-W. Ni, Y-M. Kan, and G-J. Zhang: In situ synthesis of ZrB2–MoSi2 platelet composites: Reactive hot pressing process, microstructure and mechanical properties. Ceram. Int. 38, 4751 (2012).

H.L. Zhao, J.L. Wang, Z.M. Zhu, J. Wang, and W. Pan: Mechanical properties and microstructure of in situ synthesized ZrB2–ZrN1−x composites. J. Mater. Sci. 41, 1769 (2006).

H. Zhao, J. Wang, Z. Zhu, W. Pan, and J. Wang: In situ synthesis mechanism of ZrB2–ZrN composite. Mater. Sci. Eng., A 452–453, 130 (2007).

W-W. Wu, M. Estili, T. Nishimura, G-J. Zhang, and Y. Sakka: Machinable ZrB2–SiC–BN composites fabricated by reactive spark plasma sintering. Mater. Sci. Eng., A 582, 41 (2013).

E. Breval and W.B. Johnson: Microstructure of platelet-reinforced ceramics prepared by the directed reaction of zirconium with boron carbide. J. Am. Ceram. Soc. 75, 2139 (1992).

W-W. Wu, G-J. Zhang, Y.M. Kan, and Y. Sakka: Synthesis, microstructure and mechanical properties of reactively sintered ZrB2–SiC–ZrN composites. Ceram. Int. 39, 7273 (2013).

Q. Qu, J. Han, W. Han, X. Zhang, and C. Hong: In situ synthesis mechanism and characterization of ZrB2–ZrC–SiC ultra high-temperature ceramics. Mater. Chem. Phys. 110, 216 (2008).

J.W. Zimmermann, G.E. Hilmas, W.G. Fahrenholtz, F. Monteverde, and A. Bellosi: Fabrication and properties of reactively hot pressed ZrB2–SiC ceramics. J. Eur. Ceram. Soc. 27, 2729 (2007).

L. Rangaraj, C. Divakar, and V. Jayaram: Fabrication and mechanisms of densification of ZrB2-based ultra-high temperature ceramics by reactive hot pressing. J. Eur. Ceram. Soc. 30, 129 (2010).

Y. Zhao, L-J. Wang, G-J. Zhang, W. Jiang, and L-D. Chen: Preparation and microstructure of a ZrB2–SiC composite fabricated by the spark plasma sintering-reactive synthesis method. J. Am. Ceram. Soc. 90, 4040 (2007).

W.W. Wu, G.J. Zhang, Y.M. Kan, and P.L. Wang: Reactive hot pressing of ZrB2–SiC–ZrC ultra high-temperature ceramics at 1800 °C. J. Am. Ceram. Soc. 89, 2967 (2006).

F. Monteverde: Progress in the fabrication of ultra-high-temperature ceramics: In situ synthesis, microstructure and properties of a reactive hot pressed HfB2-SIC. Compos. Sci. Technol. 65, 1869 (2005).

W.W. Wu, G-J. Zhang, Y.M. Kan, and P-L. Wang: Reactive hot pressing of ZrB2–SiC–ZrC composites at 1600 °C. J. Am. Ceram. Soc. 91, 2501 (2000).

W-W. Wu, G-J. Zhang, Y-M. Kan, and P-L. Wang: Combustion synthesis of ZrB2–SiC composite powders ignited in air. Mater. Lett. 63, 1422 (2009).

T. Tsuchida and S. Yamamoto: Mechanical activation assisted self-propagating high-temperature synthesis of ZrC and ZrB2 in air from Zr/B/C powder mixtures. J. Eur. Ceram. Soc. 24, 45 (2004).

T. Tsuchida and S. Yamamoto: MA-SHS and SPS of ZrB2–ZrC composites. Solid State Ionics 172, 215 (2004).

W-W. Wu, W-L. Xiao, M. Estili, G-J. Zhang, and Y. Sakka: Microstructure and mechanical properties of ZrB2–SiC–BN composites fabricated by reactive hot pressing and reactive spark plasma sintering. Scr. Mater. 68, 889 (2013).

J. Zou, S.G. Huang, K. Vanmeensel, G.J. Zhang, J. Vleugels, and O. Van der Biest: Spark plasma sintering of superhard B4C–ZrB2 ceramics by carbide boronizing. J. Am. Ceram. Soc. 96, 1055 (2013).

J. Zou, J. Liu, J. Zhao, G-J. Zhang, S. Huang, B. Qian, J. Vleugels, O. Van der Biest, and J.Z. Shen: A top-down approach to densify ZrB2–SiC–BN composites with deeper homogeneity and improved reliability. Chem. Eng. J. 249, 93 (2014).

D. Wang, S. Ran, L. Shen, H. Sun, and Q. Huang: Fast synthesis of B4C–TiB2 composite powders by pulsed electric current heating TiC–B mixture. J. Eur. Ceram. Soc. 35, 1107 (2015).

D. Vallauri, I.C. Atías Adrian, and A. Chrysanthou: TiC–TiB2 composites: A review of phase relationships, processing and properties. J. Eur. Ceram. Soc. 28, 1697 (2008).

N.J. Welham: Formation of nanometric TiB2 from TiO2. J. Am. Ceram. Soc. 83, 1290 (2000).

N. Setoudeh and N.J. Welham: Formation of zirconium diboride by room temperature mechanochemical reaction between ZrO2, B2O3 and Mg. J. Alloys Compd. 420, 225 (2006).

R. Ricceri and P. Matteazzi: A fast and low-cost room temperature process for TiB2 formation by mechanosynthesis. Mater. Sci. Eng., A 379, 341 (2004).

D.L. Segal: Chemical routes for the preparation of powders. Phys. Chem. Carbides, Nitrides Borides 185, 3 (1990).

Y.D. Blum and H-J. Kleebe: Chemical reactivities of hafnium and its derived boride, carbide and nitride compounds at relatively mild temperature. J. Mater. Sci. 39, 6023 (2004).

H.R. Hoekstra and J.J. Katz: The preparation and properties of the group IV-B metal borohydrides. J. Am. Chem. Soc. 71, 2488 (1949).

W.E. Reid, J.M. Bish, and A. Brenner: Electrodeposition of metals from organic solutions. III. Preparation and electrolysis of titanium and zirconium compounds in non-aqueous media. J. Electrochem. Soc. 104, 21 (1957).

M.K. Gallagher, W.E. Rhine, and H.K. Bowen: Low-temperature route to high-purity titanium, zirconium and hafnium diboride powders and films. In Ultrastructure Processing of Advanced Ceramics, J.D. Mackenzie and D.R. Ulrich eds.; Wiley Interscience: New York, 1988; pp. 901–906.

L. Chen, Y. Gu, Z. Yang, and Y. Qian: Preparation and some properties of nanocrystalline ZrB2 powder. Scr. Mater. 50, 959 (2004).

L. Chen, Y. Gu, L. Shi, Z. Yang, J. Ma, and Y. Qian: Synthesis and oxidation of nanocrystalline HfB2. J. Alloys Compd. 368, 353 (2004).

Y. Yan, Z. Huang, S. Dong, and D. Jiang: New route to synthesize ultra-fine zirconium diboride powders using inorganic–organic hybrid precursors. J. Am. Ceram. Soc. 89, 3585 (2006).

Y.J. Yan, Z.R. Huang, S.M. Dong, and D.L. Jiang: Carbothermal preparation of ultra-fine TiB2 powders using solution-derived precursors via sol-gel method. Key Eng. Mater. 336–338, 944 (2007).

S. Venugopal, A. Paul, B. Vaidhyanathan, J.G.P. Binner, E.E. Boakye, K. Keller, P. Mogilevsky, A. Katz, and P.M. Brown: Sol–gel synthesis and formation mechanism of ultra-high temperature ceramic: HfB2. J. Am. Ceram. Soc. 97, 92 (2014).

S. Venugopal, D.D. Jayaseelan, A. Paul, B. Vaidhyanathan, J.G.P. Binner, and P.M. Brown: Screw dislocation assisted spontaneous growth of HfB2 tubes and rods. J. Am. Ceram. Soc. 98, 2060 (2015).

S. Venugopal, A. Paul, B. Vaidhyanathan, J.G.P. Binner, A. Heaton, and P.M. Brown: Synthesis and spark plasma sintering of sub-micron HfB2: Effect of various carbon sources. J. Eur. Ceram. Soc. 34, 1471 (2014).

Y. Cao, H. Zhang, F. Li, L. Lu, and S. Zhang: Preparation and characterization of ultrafine ZrB2–SiC composite powders by a combined sol–gel and microwave boro/carbothermal reduction method. Ceram. Int. 41, 7823 (2015).

Y. Xie, T.H. Sanders, and R.F. Speyer: Solution-based synthesis of submicrometer ZrB2 and ZrB2–TaB2. J. Am. Ceram. Soc. 91, 1469 (2008).

D.L. Hu, Q. Zheng, H. Gu, D.W. Ni, and G.J. Zhang: Role of WC additive on reaction, solid-solution and densification in HfB2–SiC ceramics. J. Eur. Ceram. Soc. 34, 611 (2014).

X.H. Zhang, P. Hu, J.C. Han, L. Xu, and S.H. Meng: The addition of lanthanum hexaboride to zirconium diboride for improved oxidation resistance. Scr. Mater. 57, 1036 (2007).

S.R. Levine and E.J. Opila: Tantalum addition to zirconium diboride for improved oxidation resistance. Nasa/TM-2003-212483 (2003).

F. Monteverde: Ultra-high temperature HfB2–SiC ceramics consolidated by hot-pressing and spark plasma sintering. J. Alloys Compd. 428, 197 (2007).

Y. Wang, L. Luo, J. Sun, and L. An: ZrB2–SiC(Al) ceramics with high resistance to oxidation at 1500 °C. Corros. Sci. 74, 154 (2013).

J. Han, P. Hu, X. Zhang, S. Meng, and W. Han: Oxidation-resistant ZrB2–SiC composites at 2200 °C. Compos. Sci. Technol. 68, 799 (2008).

P.A. Williams, R. Sakidja, J.H. Perepezko, and P. Ritt: Oxidation of ZrB2–SiC ultra-high temperature composites over a wide range of SiC content. J. Eur. Ceram. Soc. 32, 3875 (2012).

W.G. Fahrenholtz and G.E. Hilmas: Oxidation of ultra-high temperature transition metal diboride ceramics. Int. Mater. Rev. 57, 61 (2012).

D-W. Ni, G-J. Zhang, Y-M. Kan, and P-L. Wang: Synthesis of monodispersed fine hafnium diboride powders using carbo/borothermal reduction of hafnium dioxide. J. Am. Ceram. Soc. 91, 2709 (2008).

E. Opila and M. Halbig: Oxidation of ZrB2–SiC. Cer. Eng. Sci. Proc. 22, 221 (2008).

B. Zhao, Y. Zhang, J. Li, B. Yang, T. Wang, Y. Hu, D. Sun, R. Li, S. Yin, Z. Feng, and T. Sato: Morphology and mechanism study for the synthesis of ZrB2–SiC powders by different methods. J. Solid State Chem. 207, 1 (2013).

M.A. Avilés, J.M. Córdoba, M.J. Sayagués, M.D. Alcalá, and F.J. Gotor: Mechanosynthesis of Hf1−xZrxB2 solid solution and Hf1−xZrxB2/SiC composite powders. J. Am. Ceram. Soc. 93, 696 (2010).

D.L. McClane, W.G. Fahrenholtz, and G.E. Hilmas: Thermal properties of (Zr, TM)B2 solid solutions with TM = Ta, Mo, Re, V and Cr. J. Am. Ceram. Soc. 98, 637 (2015).

D.L. McClane, W.G. Fahrenholtz, and G.E. Hilmas: Thermal properties of (Zr, TM)B2 solid solutions with TM = Hf, Nb, W, Ti and Y. J. Am. Ceram. Soc. 97, 1552 (2014).

B. Post, F.W. Glaser, and D. Moskowitz: Transition metal diborides. Acta Metall. 2, 20 (1954).

S. Otani, T. Aizawa, and N. Kieda: Solid solution ranges of zirconium diboride with other refractory diborides: HfB2, TiB2, TaB2, NbB2, VB2 and CrB2. J. Alloys Compd. 475, 273 (2009).

W.G. Fahrenholtz, G.E. Hilmas, I.G. Talmy, and J.A. Zaykoski: Refractory diborides of zirconium and hafnium. J. Am. Ceram. Soc. 90, 1347 (2007).

Y. Jiang, R. Li, Y. Zhang, B. Zhao, J. Li, and Z. Feng: Tungsten doped ZrB2 powder synthesized synergistically by co-precipitation and solid-state reaction methods. Procedia Eng. 27, 1679 (2012).

I.G. Talmy, J.A. Zaykoski, and M.M. Opeka: High-temperature chemistry and oxidation of ZrB2 ceramics containing SiC, Si3N4, Ta5Si3 and TaSi2. J. Am. Ceram. Soc. 91, 2250 (2008).

D. Sciti, V. Medri, and L. Silvestroni: Oxidation behaviour of HfB2–15 vol% TaSi2 at low, intermediate and high temperatures. Scr. Mater. 63, 601 (2010).

S.C. Zhang, G.E. Hilmas, and W.G. Fahrenholtz: Improved oxidation resistance of zirconium diboride by tungsten carbide additions. J. Am. Ceram. Soc. 91, 3530 (2008).

S.C. Zhang, G.E. Hilmas, and W.G. Fahrenholtz: Oxidation of zirconium diboride with tungsten carbide additions. J. Am. Ceram. Soc. 94, 1198 (2011).

R. He, X. Zhang, W. Han, P. Hu, and C. Hong: Effects of solids loading on microstructure and mechanical properties of HfB2–20 vol% MoSi2 ultra high temperature ceramic composites through aqueous gelcasting route. Mater. Des. 47, 35 (2013).

ACKNOWLEDGMENTS

This manuscript was conceived and drafted as part of an extended visit by WGF to the University of Birmingham during the spring of 2015. The authors wish to thank the U.K. Engineering and Physical Science Research Council (EPSRC) for financial support through the Materials Systems for Extreme Environments (XMAT) program.

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/jmr-editor-manuscripts/.

Rights and permissions

About this article

Cite this article

Fahrenholtz, W.G., Binner, J. & Zou, J. Synthesis of ultra-refractory transition metal diboride compounds. Journal of Materials Research 31, 2757–2772 (2016). https://doi.org/10.1557/jmr.2016.210

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.210