Abstract

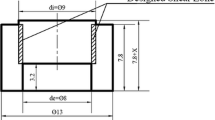

Dynamic loading of the hat-shaped specimen of 2195-T6 aluminum lithium alloy was carried out with a split Hopkinson pressure bar at ambient temperature. The formation and evolution mechanisms of adiabatic shear band (ASB) in this alloy were investigated and then microstructure was further observed. The microstructure within ASB in 2195 aluminum alloy was characterized by means of optical microscopy and transmission electron microscopy. The width of ASB was about 20–30 um. Nano-grains (50–100 nm) were observed in the middle of shear zone. Experimental results show that the diffusive transformation took place within ASB during high strain rate deformation, namely the precipitates dissolving in the matrix in the process (within about 71 µs). Based on thermodynamics and kinetics analyses, dissolution of precipitates was firstly investigated during adiabatic shearing deformation, and a dissolution model was suggested in the present work. The diffusive transformation and the microstructure evolution within ASB in 2195 alloy were explained.

Similar content being viewed by others

References

C. Kennedy and L.E. Murr: Comparison of tungsten heavy-alloy rod penetration into ductile and hard metal targets: Microstructural analysis and computer simulations. Mater. Sci. Eng., A 325, 131 (2002).

Q. Xue, J.F. Bingert, B.L. Henrie, and G.T. Gray, III: EBSD characterization of dynamic shear band regions in pre-shocked and as-received 304 stainless steels. Mater. Sci. Eng., A 473, 279 (2008).

Y. Yang and B.F. Wang: Dynamic recrystallization in adiabatic shear band in α-titanium. Mater. Lett. 60, 2198 (2006).

M.A. Meyers: Dynamic Behavior of Materials (John Wiley & Sons, New York, 1994).

G.E. Duvall and R.A. Graham: Phase transitions under shock-wave loading. Rev. Mod. Phys. 49, 523 (1977).

F.P. Yuan, X.D. Bian, P. Jiang, M.X. Yang, and X.L. Wu: Dynamic shear response and evolution mechanisms of adiabatic shear band in an ultrafine-grained austenite–ferrite duplex steel. Mech. Mater. 89, 47 (2015).

M.A. Meyers, Y.B. Xu, Q. Xue, M.T. Pérez-Prado, and T.R. McNelley: Microstructural evolution in adiabatic shear localization in stainless steel. Acta Mater. 51, 1307 (2003).

B.F. Wang and Y. Yang: Microstructure evolution in adiabatic shear band in fine-grain-sized Ti–3Al–5Mo–4.5V alloy. Mater. Sci. Eng., A 473, 306 (2008).

Y.B. Xu, Y.L. Bai, and M.A. Meyers: Deformation, phase transformation and recrystallization in the shear bands induced by high-strain rate loading in titanium and its alloys. J. Mater. Sci. Technol. 22, 737 (2006).

Y. Yang, F. Jiang, B.M. Zhou, X.M. Li, H.G. Zheng, and Q.M. Zhang: Microstructural characterization and evolution mechanism of adiabatic shear band in a near beta-Ti alloy. Mater. Sci. Eng., A 528, 2787 (2011).

D.H. Li, Y. Yang, T. Xu, H.G. Zheng, Q.S. Zhu, and Q.M. Zhang: Observation of the microstructure in the adiabatic shear band of 7075 aluminum alloy. Mater. Sci. Eng., A 527, 3529 (2010).

L.W. Meyer, S. Manwaring, and L.E. Murr: Metallurgical Applications of Shock-Wave and High-Strain-Rate Phenomena, Vol. 529 (Marcel Decker, New York, 1986).

U. Andrade, M.A. Meyers, and K.S. Vecchio: Dynamic recrystallization in high-strain, high-strain-rate plastic deformation of copper. Acta Metall. Mater. 42, 3183 (1994).

R.S. Culver: Thermal Instability Strain in Dynamic Plastic Deformation (Springer, US, 1973); pp. 519–530.

Y. Yang, X.M. Zhang, Z.H. Li, and Q.Y. Li: Adiabatic shear band on the titanium side in the Ti/mild steel explosive cladding interface. Acta Mater. 44, 561 (1996).

G.E. Duvall: Metallurgical Effects at High Strain Rates, 1st ed. (Plenum Press, New York, 1973); pp. 531–543.

Z. Liu, S. Bai, X. Zhou, X.W. Zhou, and Y.X. Gu: On strain-induced dissolution of θ′ and θ particles in Al–Cu binary alloy during equal channel angular pressing. Mater. Sci. Eng., A 528, 2217 (2011).

M. Murayama, Z. Horita, and K. Hono: Microstructure of two-phase Al–1.7 at% Cu alloy deformed by equal-channel angular pressing. Acta Mater. 49, 21 (2001).

F.C. Ma, W.J. Lu, J.N. Qin, and D. Zhang: Microstructure evolution of near-α titanium alloys during thermomechanical processing. Mater. Sci. Eng., A 416, 59 (2006).

Y. Wang, W. Shao, and L. Zhen: Dissolution behavior of δ phase and its effects on deformation mechanism of GH4169 alloy. Chin. J. of Nonferrous Met. 21, 341 (2011).

H.Y. Zhang, S.H. Zhang, M. Cheng, and Z.X. Li: Deformation characteristics of δ phase in the delta-processed Inconel 718 alloy. Mater. Charact. 61, 49 (2010).

A.R. Wazzan and J.E. Dorn: Analysis of enhanced diffusivity in nickel. J. Appl. Phys. 36, 222 (1965).

A.L. Ruoff and R.W. Balluffi: Strain-enhanced diffusion in metals. II. Dislocation and grain-boundary short-circuiting models. J. Appl. Phys. 34, 1848 (2004).

M. Cohen: Self-diffusion during plastic deformation. Trans. Jpn. Inst. Met. 11, 145 (1970).

Y. Ivanisenko, W. Lojkowski, R.Z. Valiev, and H-J. Fecht: The mechanism of formation of nanostructure and dissolution of cementite in a pearlitic steel during high pressure torsion. Acta Mater. 51, 5555 (2003).

A.L. Ruoff: Enhanced diffusion during plastic deformation by mechanical diffusion. J. Appl. Phys. 38, 3999 (2004).

N. Dolgopolov, A. Rodin, A. Simanov, and I. Gontar: Cu diffusion along Al grain boundaries. Mater. Lett. 62, 4477 (2008).

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation (No. 51274245, No. 51574290), NSAF (No. U1330126), the Ph.D. Programs Foundation of Ministry of Education of China (No. 20120162130006), the Hunan Provincial Natural Science Foundation of China (No. 14JJ2011), and the key project of State Key Laboratory of Explosion Science and Technology (No. KFJJ11-1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Y., Luo, S., Hu, H. et al. Diffusive transformation at high strain rate: On instantaneous dissolution of precipitates in aluminum alloy during adiabatic shear deformation. Journal of Materials Research 31, 1220–1228 (2016). https://doi.org/10.1557/jmr.2016.151

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.151