Abstract

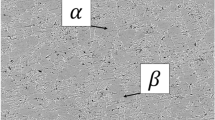

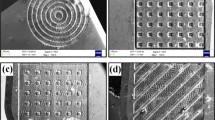

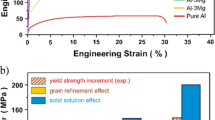

A carbide cutting tool is widely used in machining process due to its availability and being cheaper than a better performance cutting tool, such as cubic boron nitride. The carbide cutting tool also has substantial hardness and toughness that is suitable to be applied in intermittent cutting. This paper presents the case study of a wear mechanism experienced on the cutting edge of the coated and uncoated carbide tools in turning and milling processes. The wear mechanisms of carbide cutting tools were investigated in machining Inconel 718, titanium alloy Ti–6Al–4V extra-low interstitial, and aluminum metal matrix composite (AlSi/AlN MMC) at their high cutting speed regime. The tools failed primarily due to wear on the flank and rake faces. The failure mode of the carbide cutting tools was similar regardless of the machining operations and coating is believed to enhance the tool life, but once removed, the tool fails similar to that with the uncoated tool.

Similar content being viewed by others

References

I.M. Hutchings: Abrasive and erosive wear tests for thin coatings: A unified approach. Tribol. Int. 31, 5–15 (1998).

Z. Wang and Q. Zhou: Applying a population growth model to simulate wear of rough surfaces during running-in. Wear 294–295, 356–363 (2012).

Y.S. Liao, H.M. Lin, and J.H. Wang: Behaviors of end milling Inconel 718 superalloy by cemented carbide tools. J. Mater. Process. Technol. 201, 460–465 (2008).

A.R.C. Sharman, J.I. Hughes, and K. Ridgway: Workpiece surface integrity and tool life issues when turning inconel 718™ nickel based superalloy. Mach. Sci. Technol. 8, 399–414 (2004).

K. Srinivasulu and B.K. Subhash: Studies On The Residual Stresses Due To Machining On Super Alloy Inconel-718. In International Conference on Aerospace Science and Technology, Bangalore, India, 2008.

M. Alauddin, M.A. El Baradie, and M.S.J. Hashmi: Optimization of surface finish in end milling Inconel 718. J. Mater. Process. Technol. 56, 54–65 (1996).

E. Bradley: Superalloys. In ASM International, Metal Park, 1988.

H.R. Krain, A.R.C. Sharman, and K. Ridgway: Optimisation of tool life and productivity when end milling Inconel 718TM. J. Mater. Process. Technol. 189, 153–161 (2007).

A. Sharman, R.C. Dewes, and D.K. Aspinwall: Tool life when high speed ball nose end milling Inconel 718. J. Mater. Process. Technol. 118, 29–35 (2001).

C.H. Che-Haron and A. Jawaid: The effect of machining on surface integrity of titanium alloy Ti-6% Al-4% V. J. Mater. Process. Technol. 166, 188–192 (2005).

Z.M. Wang and E.O. Ezugwu: Performance of PVD-coated carbide tools when machining Ti-6Al-4V©. Tribol. Trans. 40, 81–86 (1997).

A. Jawaid, S. Sharif, and S. Koksal: Evaluation of wear mechanisms of coated carbide tools when face milling titanium alloy. J. Mater. Process. Technol. 99, 266–274 (2000).

N. Muthukrishnan, M. Murugan, and K.P. Rao: An investigation on the machinability of Al-SiC metal matrix composites using pcd inserts. Int. J. Adv. Manuf. Technol. 38, 447–454 (2008).

R. Vaziri, D. Delfosse, G. Pageau, and A. Poursartip: High-speed impact response of particulate metal matrix composite materials—An experimental and theoretical investigation. Int. J. Impact Eng. 13, 329–352 (1993).

S. Barnes, I.R. Pashby, and D.K. Mok: The effect of workpiece temperature on the machinability of an aluminum/SiC MMC. J. Manuf. Sci. Eng., Trans. ASME 118, 422–427 (1996).

P.J. Heath: Developments in applications of PCD tooling. J. Mater. Process. Technol. 116, 31–38 (2001).

N.P. Hung, S.H. Yeo, and B.E. Oon: Effect of cutting fluid on the machinability of metal matrix composites. J. Mater. Process. Technol. 67, 157–161 (1997).

Y. Yang, R. Boom, B. Irion, D-J. van Heerden, P. Kuiper, and H. de Wit: Recycling of composite materials. Chem. Eng. Process.: Process Intensif. 51, 53–68 (2012).

X. Ding, W.Y.H. Liew, and X.D. Liu: Evaluation of machining performance of MMC with PCBN and PCD tools. Wear 259, 1225–1234 (2005).

L.A. Looney, J.M. Monaghan, P. O’Reilly, and D.M.R. Taplin: The turning of an Al/SiC metal-matrix composite. J. Mater. Process. Technol. 33, 453–468 (1992).

N.P. Hung, F.Y.C. Boey, K.A. Khor, C.A. Oh, and H.F. Lee: Machinability of cast and powder-formed aluminum alloys reinforced with SiC particles. J. Mater. Process. Technol. 48, 291–297 (1995).

S. Durante, G. Rutelli, and F. Rabezzana: Aluminum-based MMC machining with diamond-coated cutting tools. Surf. Coat. Technol. 94–95, 632–640 (1997).

M.S. Kasim, C.H. Che Haron, J.A. Ghani, M.A. Sulaiman, and M.Z.A. Yazid: Wear mechanism and notch wear location prediction model in ball nose end milling of Inconel 718. Wear 302, 1171–1179 (2013).

A. Jawaid, S. Koksal, and S. Sharif: Cutting performance and wear characteristics of PVD coated and uncoated carbide tools in face milling Inconel 718 aerospace alloy. J. Mater. Process. Technol. 116, 2–9 (2001).

M. El-Gallab and M. Sklad: Machining of Al/SiC particulate metal matrix composites: Part II: Workpiece surface integrity. J. Mater. Process. Technol. 83, 277–285 (1998).

C.J.E. Andrewes, H-Y. Feng, and W.M. Lau: Machining of an aluminum/SiC composite using diamond inserts. J. Mater. Process. Technol. 102, 25–29 (2000).

M.A. Sulaiman, C.H. Che Haron, J.A. Ghani, and M.S. Kasim: The study of wear process on uncoated carbide cutting tool in machining titanium alloy. J. Appl. Sci. Res. 8, 4821–4827 (2012).

J.A. Arsecularatne, L.C. Zhang, and C. Montross: Wear and tool life of tungsten carbide, PCBN and PCD cutting tools. Int. J. Mach. Tools Manuf. 46, 482–491 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghani, J.A., Che Haron, C.H., Kasim, M.S. et al. Wear mechanism of coated and uncoated carbide cutting tool in machining process. Journal of Materials Research 31, 1873–1879 (2016). https://doi.org/10.1557/jmr.2015.382

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.382