Abstract

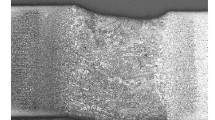

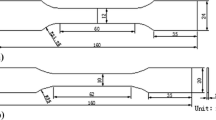

This study was to analyze the microstructure, microhardness, tensile and fatigue performance of the welded joints performed by a fiber laser on 22MnB5 and dual-phase steels (DP590, DP980) in similar and dissimilar combinations. The result shows that the weld zone (WZ) basically consisted of lath martensite. The HAZ in these steels can be divided into 3 parts: quenched, incomplete quenched, and tempered region. The WZ had the highest hardness, and a soft zone existed in the HAZ of all steels. Inside the WZ of the dissimilar welded joints, two hardness subregions were observed due to the difference in the alloying elements of these steels. Tensile specimens of the 22MnB5–22MnB5 and 22MnB5–DP980 welded joints were all broken in HAZ, while the 22MnB5–DP590 welded joints failed in the DP590 base metal (BM). The BM had a higher fatigue life than the welded joints, and the fatigue failure of the 22MnB5 similar and 22MnB5–DP980 dissimilar welded joints respectively occurred in the HAZ and DP980 BM. The fatigue fracture contained 3 parts: crack initiation, crack propagation, and the final fast fracture region.

Similar content being viewed by others

References

X. Cao and M. Jahazi: Effect of welding speed on butt joint quality of Ti-6Al-4V alloy welded using a high-power Nd: YAG laser. Opt. Laser Eng. 47, 1231 (2009).

Y.W. Park, H. Park, S. Rhee, and M. Kang: Real time estimation of CO2 laser weld quality for automotive industry. Opt. Laser Technol. 34, 136 (2002).

M. Sokolov, A. Salminen, M. Kuznetsov, and I. Tsibulskiy: Laser welding and weld hardness analysis of thick section S355 structural steel. Mater. Des. 32, 5127, (2011).

H. Karbasian and A.E. Tekkaya: A review on hot stamping. J. Mater. Process. Technol. 210, 2103 (2010).

C.H. Kim, J.K. Choi, M.J. Kang, and Y.D. Park: A study on the CO2 laser welding characteristics of high strength steel up to 1500MPa for automotive application. J. Achiev. Mater. Manuf. Eng. 39, 79 (2010).

S. Hyunwoo, F. Dennis, H. Hartmut, G. Roland, and S. Mirko: An investigation of the blanking process of the quenchable boron alloyed steel 22MnB5 before and after hot stamping process. J. Mater. Process. Technol. 212, 437 (2012).

W. Chen, P. Ackerson, and P. Molian: CO2 laser welding of galvanized steel sheets using vent holes. Mater. Des. 30, 245 (2009).

A. Ribolla, G.L. Damoulis, and G.F. Batalha: The use of Nd: YAG laser weld for large scale volume assembly of automotive body in white. J. Mater. Process. Technol. 164, 1120 (2005).

M. Xia, N. Sreenivasan, S. Lawson, Y. Zhou, and Z.A. Tian: Comparative study of formability of diode laser welds in DP980 and HSLA steels. ASME Trans. 129, 446 (2009).

Q. Wu, J. Gong, G. Chen, and L. Xu: Research on laser welding of vehicle body. Opt. Laser Technol. 40, 420 (2009).

N. Farabi, D.L. Chen, and Y. Zhou: Microstructure and mechanical properties of laser welded dissimilar DP600/DP980 dual-phase steel joints. J. Alloys Compd. 509, 982 (2011).

L. Quinto, A. Costa, R. Miranda, D. Yapp, V. Kumar, and C.J. Kong: Welding with high power fiber lasers–A preliminary study. Mater. Des. 28, 1231 (2007).

H.C. Chen, A.J. Pinkerton, L. Li, Z. Liu, and A.T. Mistry: Gap-free fibre laser welding of Zn-coated steel on Al alloy for light-weight automotive applications. Mater. Des. 32, 495 (2011).

C.Y. Cui, X.G. Cui, X.D Ren, T.T. Liu, J.D. Hu, and Y.M. Wang: Microstructure and microhardness of fiber laser butt welded joint of stainless steel plates. Mater. Des. 49, 761 (2013).

J. Jia, S.L. Yang, W.Y. Ni, J.Y. Bai, and B. Ding: Study on microstructure and properties of laser welding joints of marine high strength steel E36. Chin. J. Lasers 41, 0203002 (2014).

M.S. Xia, E. Biro, Z.L. Tian, and Y. Zhou: Effects of heat input and martensite on HAZ softening in laser welding of dual phase steels. ISIJ Int. 48, 809 (2008).

T.K. Han, B.G. Park, and C.Y. Kang: Hardening characteristics of CO2 laser welds in advanced high strength steel. Met. Mater. Int. 18, 473 (2012).

A. Turetta, S. Bruschi, and A. Ghiotti: Investigation of 22MnB5 formability in hot stamping operations. J. Mater. Process. Technol. 177, 396 (2006).

M.Y. Liu, B. Shi, C. Wang, S.K. Ji, X. Cai, and H.W. Song: Normal Hall-Petch behavior of mild steel with submicron grains. Mater. Lett. 5, 2798 (2003).

V.A. Grishunin, V.E. Gromov, Y.F. Ivanov, K.V. Volkov, and S.V. Konovalov: Evolution of the phase composition and defect substructure in the surface layer of rail steel under fatigue. Steel Transl. 43, 724 (2013).

T. Takeda, Y. Shindo, and F. Narita: Vacuum crack growth behavior of austenitic stainless steel under fatigue loading. Strength Mater. 43, 532 (2011).

ACKNOWLEDGMENTS

The authors sincerely would like to thank Dr. Yan from the College of Materials Engineering, Shanghai University of Engineering Science, for his help in preparation of the specimens and helpful discussions. This research was supported by Shanghai Key Technology Development Center of High Intelligent Laser Processing and Equipment Production (Shanghai University of Engineering Science). This work was financially supported by National Natural Science Foundation of China (Project No. 51075256), and a state key project (No. 11ZZ177).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, J., Yang, SL., Ni, WY. et al. Microstructure and mechanical properties of fiber laser welded joints of ultrahigh-strength steel 22MnB5 and dual-phase steels. Journal of Materials Research 29, 2565–2575 (2014). https://doi.org/10.1557/jmr.2014.273

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.273