Abstract

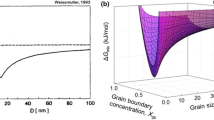

Grain boundary segregation provides a method for stabilization of nanocrystalline metals—an alloying element that will segregate to the boundaries can lower the grain boundary energy, attenuating the driving force for grain growth. The segregation strength relative to the mixing enthalpy of a binary system determines the propensity for segregation stabilization. This relationship has been codified for the design space of positive enthalpy alloys; unfortunately, quantitative values for the grain boundary segregation enthalpy exist in only very few material systems, hampering the prospect of nanocrystalline alloy design. Here we present a Miedema-type model for estimation of grain boundary segregation enthalpy, with which potential nanocrystalline phase-forming alloys can be rapidly screened. Calculations of the necessary enthalpies are made for ∼2500 alloys and used to make predictions about nanocrystalline stability.

Similar content being viewed by others

References

J. Weissmüller: Alloy effects in nanostructures. Nanostruct. Mater. 3(1–6), 261 (1993).

J. Weissmüller: Some basic notions on nanostructured solids. Mater. Sci. Eng., A 179-180(Part 1), 102 (1994).

R. Kirchheim: Grain coarsening inhibited by solute segregation. Acta Mater. 50(2), 413 (2002).

F. Liu and R. Kirchheim: Nano-scale grain growth inhibited by reducing grain boundary energy through solute segregation. J. Cryst. Growth 264(1–3), 385 (2004).

R. Kirchheim: Reducing grain boundary, dislocation line and vacancy formation energies by solute segregation. I. Theoretical background. Acta Mater. 55(15), 5129 (2007).

S.M. Foiles: Calculation of grain-boundary segregation in Ni-Cu alloys. Phys. Rev. B 40(17), 11502 (1989).

Y. Purohit, S. Jang, D.L. Irving, C.W. Padgett, R.O. Scattergood, and D.W. Brenner: Atomistic modeling of the segregation of lead impurities to a grain boundary in an aluminum bicrystalline solid. Mater. Sci. Eng., A 493(1–2), 97 (2008).

A.J. Detor and C.A. Schuh: Grain boundary segregation, chemical ordering and stability of nanocrystalline alloys: Atomistic computer simulations in the Ni–W system. Acta Mater. 55(12), 4221 (2007).

M. Menyhard, M. Yan, and V. Vitek: Atomistic vs phenomenological approaches to grain boundary segregation: Computer modeling of Cu-Ag alloys. Acta Metall. et Mater. 42(8), 2783 (1994).

A. Kirchner and B. Kieback: Thermodynamic model of alloy grain boundaries. Scr. Mater. 64(5), 406 (2011).

P. Lejcek: Grain Boundary Segregation in Metals Vol. 136 (Springer, Berlin, Germany, 2010).

U. Alber, H. Müllejans, and M. Rühle: Bismuth segregation at copper grain boundaries. Acta Mater. 47(15–16), 4047 (1999).

L.S. Chang and K.B. Huang: Temperature dependence of the grain boundary segregation of Bi in Ni polycrystals. Scr. Mater. 51(6), 551 (2004).

Z. Chen, F. Liu, X. Yang, C. Shen, and Y. Fan: Analysis of controlled-mechanism of grain growth in undercooled Fe–Cu alloy. J. Alloys Compd. 509(25), 7109 (2011).

F. Liu: Grain growth in nanocrystalline Fe-Ag thin film. Mater. Lett. 59(11), 1458 (2005).

J. Weissmüller, W. Krauss, T. Haubold, R. Birringer, and H. Gleiter: Atomic structure and thermal stability of nanostructured Y-Fe alloys. Nanostruct. Mater. 1(6), 439 (1992).

X. Chen and J. Mao: Thermal stability and tensile properties of electrodeposited Cu-Bi alloy. J. Mater. Eng. Perform. 20(3), 481 (2011).

K.A. Darling, B.K. VanLeeuwen, C.C. Koch, and R.O. Scattergood: Thermal stability of nanocrystalline Fe-Zr alloys. Mater. Sci. Eng., A 527(15), 3572 (2010).

C.E. Krill, H. Ehrhardt, and R. Birringer: Thermodynamic stabilization of nanocrystallinity. Z. Metallkd. 96(10), 1134 (2005).

M. Atwater, H. Bahmanpour, R. Scattergood, and C. Koch: The thermal stability of nanocrystalline cartridge brass and the effect of zirconium additions. J. Mater. Sci. 148(1), 220–226 (2012).

P. Choi, M. da Silva, U. Klement, T. Al-Kassab, and R. Kirchheim: Thermal stability of electrodeposited nanocrystalline Co-1.1at.%P. Acta Mater. 53(16), 4473 (2005).

M.A. Atwater, D. Roy, K.A. Darling, B.G. Butler, R.O. Scattergood, and C.C. Koch: The thermal stability of nanocrystalline copper cryogenically milled with tungsten. Mater. Sci. Eng., A 558, 226 (2012).

M.A. Atwater, R.O. Scattergood, and C.C. Koch: The stabilization of nanocrystalline copper by zirconium. Mater. Sci. Eng., A 559, 250 (2013).

D. Osmola, P. Nolan, U. Erb, G. Palumbo, and K.T. Aust: Microstructural evolution at large driving forces during grain growth of ultrafine-grained Ni–1.2wt%P. Phys. Status Solidi A 131(2), 569 (1992).

A.A. Talin, E.A. Marquis, S.H. Goods, J.J. Kelly, and M.K. Miller: Thermal stability of Ni-Mn electrodeposits. Acta Mater. 54(7), 1935 (2006)

E. Pellicer, A. Varea, K.M. Sivaraman, S. Pane, S. Surinach, M. Dolors Baro, J. Nogues, B.J. Nelson, and J. Sort: Grain boundary segregation and interdiffusion effects in nickel-copper alloys: An effective means to improve the thermal stability of nanocrystalline nickel. ACS Appl. Mater. Interfaces 3(7) 2265 (2011).

Y.R. Abe, J.C. Holzer, and W.L. Johnson: Formation and stability of nanocrystalline Nb-Cu alloys In Structure and Properties of Interfaces in Materials, edited by C.L. Briant, W.A.T. Clark, and U. Dahmen (Mater. Res. Soc. Symp. Proc. 238, Warrendale, PA 1991), p. 721.

A.J. Detor and C.A. Schuh: Microstructural evolution during the heat treatment of nanocrystalline alloys. J. Mater. Res. 22(11), 3233 (2007).

B.K. VanLeeuwen, K.A. Darling, C.C. Koch, R.O. Scattergood, and B.G. Butler: Thermal stability of nanocrystalline Pd81Zr19. Acta Mater. 58(12), 4292 (2010).

M. da Silva, C. Wille, U. Klement, P. Choi, and T. Al-Kassab: Electrodeposited nanocrystalline Co-P alloys: Microstructural characterization and thermal stability. Mater. Sci. Eng., A 445-446, 31 (2007).

B. Färber, E. Cadel, A. Menand, G. Schmitz, and R. Kirchheim: Phosphorus segregation in nanocrystalline Ni-3.6 at.% P alloy investigated with the tomographic atom probe (TAP). Acta Mater. 48(3), 789 (2000).

T. Hentschel, D. Isheim, R. Kirchheim, F. Muller, and H. Kreye: Nanocrystalline Ni-3.6 at.% P and its transformation sequence studied by atom-probe field-ion microscopy. Acta Mater. 48(4), 933 (2000).

S.C. Mehta, D.A. Smith, and U. Erb: Study of grain growth in electrodeposited nanocrystalline nickel-1.2 wt% phosphorus alloy. Mater. Sci. Eng., A 204(1–2), 227 (1995).

J. Eckert, J.C. Holzer, and W.L. Johnson: Thermal-stability and grain-growth behavior of mechanically alloyed nanocrystalline Fe-Cu alloys. J. Appl. Phys. 73(1), 131 (1993).

E. Rouya, G.R. Stafford, U. Bertocci, J.J. Mallett, R. Schad, M.R. Begley, R.G. Kelly, M.L. Reed, and G. Zangari: Electrodeposition of metastable Au-Ni alloys. J. Electrochem. Soc. 157(7), D396 (2010).

K.J. Bryden and J.Y. Ying: Thermal stability and hydrogen absorption characteristics of palladium-yttrium nanoalloys. Acta Mater. 44(9), 3847 (1996).

J.R. Trelewicz and C.A. Schuh: Grain boundary segregation and thermodynamically stable binary nanocrystalline alloys. Phys. Rev. B 79(9), 094112 (2009).

T. Chookajorn, H.A. Murdoch, and C.A. Schuh: Design of stable nanocrystalline alloys. Science 337(6097), 951 (2012).

H.A. Murdoch and C.A. Schuh: Stability of binary nanocrystalline alloys against grain growth and phase separation. Acta Mater. 61(6), 2121 (2013).

P. Lejcek and S. Hofmann: Thermodynamic state functions of interfacial segregation and their role in the compensation effect. Rev. Adv. Mater. Sci. 21(1), 27 (2009).

E.D. Hondros and M.P. Seah: The theory of grain boundary segregation in terms of surface adsorption analogues. Metall. Trans. A 8(9), 1363 (1977).

M.P. Seah: Grain boundary segregation. J. Phys. F: Metal Phys. 10(6), 1043 (1980).

D. McLean: Grain boundaries in metals (Oxford Clarendon Press, London, UK, 1957).

P. Wynblatt and D. Chatain: Anisotropy of segregation at grain boundaries and surfaces. Metall. Mater. Trans. A 37(9), 2595 (2006).

K.A. Darling, B.K. VanLeeuwen, J.E. Semones, C.C. Koch, R.O. Scattergood, L.J. Kecskes, and S.N. Mathaudhu: Stabilized nanocrystalline iron-based alloys: Guiding efforts in alloy selection. Mater. Sci. Eng., A 528(13–14), 4365 (2011).

C.L. Briant: Solid solubility and grain boundary segregation. Philos. Mag. Lett. 73(6), 345 (1996).

J. Friedel: Electronic structure of primary solid solutions in metals. Adv. Phys. 3(12), 446 (1954).

P. Wynblatt and Z. Shi: Relation between grain boundary segregation and grain boundary character in FCC alloys. J. Mater. Sci. 40(11), 2765 (2005).

D. Udler and D.N. Seidman: Solute segregation at [001] tilt boundaries in dilute f.c.c. alloys. Acta Mater. 46(4), 1221 (1998).

D. Udler and D.N. Seidman: Solute-atom segregation at (002) twist boundaries in dilute Ni–Pt alloys: Structural/chemical relations. Acta Metall. Mater. 42(6), 1959 (1994).

D. Udler and D.N. Seidman: Solute-atom segregation at high-angle (002) twist boundaries in dilute Au-Pt alloys. J. Mater. Res. 10(8), 1933 (1995).

O. Duparc, A. Larere, B. Lezzar, O. Khalfallah, and V. Paidar: Comparison of the intergranular segregation for eight dilute binary metallic systems in the Σ 11′ 332 tilt grain boundary. J. Mater. Sci. 40(12), 3169 (2005).

Y. Purohit, L. Sun, D.L. Irving, R.O. Scattergood, and D.W. Brenner: Computational study of the impurity induced reduction of grain boundary energies in nano- and bi-crystalline Al-Pb alloys. Mater. Sci. Eng., A 527(7–8), 1769 (2010).

H. Bakker: Enthalpies in Alloys: Miedema’s Semi-empirical Model (Trans Tech Publications, Enfield, New Hampshire, 1998).

F.R. de Boer, R. Boom, W.C.M. Mattens, A.R. Miedema, and A.K. Niessen: Cohesion in Metals: Transition Metal Alloys (North-Holland, Amsterdam, Netherlands, 1988).

A.R. Miedema: Surface segregation in alloys of transition-metals. Z. Metallkd. 69(7), 455 (1978).

O. Redlich and A.T. Kister: Algebraic representation of thermodynamic properties and the classification of solutions. Ind. Eng. Chem. 40(2), 345 (1948).

I.H. Moon, S.S. Ryu, S.W. Kim, D.M. Won, and W.S. Jang: Grain growth in the nanocrystalline W-Cu and Cu-Pb composite powders prepared by mechanical alloying. Z. Metallkd. 92(8), 986 (2001).

S.G. Mayr and D. Bedorf: Stabilization of Cu nanostructures by grain boundary doping with Bi: Experiment versus molecular dynamics simulation. Phys. Rev. B 76(2), 024111 (2007).

M. Zhu, Z. Wu, M. Zeng, L. Ouyang, and Y. Gao: Bimodal growth of the nanophases in the dual-phase composites produced by mechanical alloying in immiscible Cu–Ag system. J. Mater. Sci. 43(9), 3259 (2008).

Z.F. Wu, M.Q. Zeng, L.Z. Ouyang, X.P. Zhang, and M. Zhu: Ostwald ripening of Pb nanocrystalline phase in mechanically milled Al-Pb alloys and the influence of Cu additive. Scr. Mater. 53(5), 529 (2005).

F. Liu: Precipitation of a metastable Fe(Ag) solid solution upon annealing of supersaturated Fe(Ag) thin film prepared by pulsed laser deposition. Appl. Phys. A 81(5), 1095 (2005).

E. Pellicer, A. Varea, S. Pane, B.J. Nelson, E. Menendez, M. Estrader, S. Surinach, M.D. Baro, J. Nogues, and J. Sort: Nanocrystalline electroplated Cu-Ni: Metallic thin films with enhanced mechanical properties and tunable magnetic behavior. Adv. Funct. Mater. 20(6), 983 (2010).

Acknowledgments

This research was supported primarily by the U.S. Army Research Office under contract W911NF-09-1-0422, with partial additional support from the Solid State Solar Thermal Energy Conversion (S3TEC), an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences under DE-SC0001299.

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

Supplementary Material

Supplementary materials can be viewed in this issue of the Journal of Materials Research by visiting http://journals.cambridge.org/jmr.

Rights and permissions

About this article

Cite this article

Murdoch, H.A., Schuh, C.A. Estimation of grain boundary segregation enthalpy and its role in stable nanocrystalline alloy design. Journal of Materials Research 28, 2154–2163 (2013). https://doi.org/10.1557/jmr.2013.211

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.211