Abstract

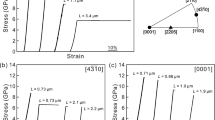

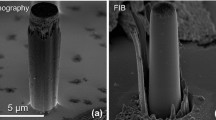

This article describes cracking during microcompression of Si, InAs, MgO, and MgAl2O4 crystals and compares this with previous observations on Si and GaAs micropillars. The most common mode of cracking was through-thickness axial splitting, the crack growing downward from intersecting slip bands in pillars above a critical size. The splitting behavior observed in all of these materials was quantitatively consistent with a previous analysis, despite the differences in properties and slip geometry between the different materials. Cracking above the slip bands also occurred either in the side or in the top surface of some pillars. The driving forces for these modes of cracking are described and compared with observations. However, only through-thickness axial splitting was observed to give complete failure of the pillar; it is, therefore, considered to be the most important in determining the brittle-to-ductile transitions that have been observed.

Similar content being viewed by others

References

M.D. Uchic, D.M. Dimiduk, J.N. Florando, and W.D. Nix: Sample dimensions influence strength and crystal plasticity. Science 305, 986 (2004).

J.R. Greer and W.D. Nix: Size dependence of mechanical properties of gold at the sub-micron scale. Appl. Phys. A 80, 1625 (2005).

H. Bei, S. Shim, E.P. George, M. Miller, E. Herbert, and G. Pharr: Compressive strengths of molybdenum alloy micro-pillars prepared using a new technique. Scr. Mater. 57, 397 (2007).

F. Östlund, P.R. Howie, R. Ghisleni, S. Korte, K. Leifer, W.J. Clegg, and J. Michler: Ductile-brittle transition in micropillar compression of GaAs at room temperature. Philos. Mag. 91, 1190 (2011).

F. Östlund, K. Rzepiejewska-Malyska, K. Leifer, L.M. Hale, Y. Tang, R. Ballarini, W.W. Gerberich, and J. Michler: Brittle-to-ductile transition in uniaxial compression of silicon pillars at room temperature. Adv. Funct. Mater. 19, 2439 (2009).

J. Michler, K. Wasmer, S. Meier, F. Östlund, and K. Leifer: Plastic deformation of gallium arsenide micropillars under uniaxial compression at room temperature. Appl. Phys. Lett. 90, 043123 (2007).

S. Korte and W.J. Clegg: Discussion of the dependence of the effect of size on the yield stress in hard materials studied by microcompression of MgO. Philos. Mag. 91, 1150 (2010).

S.J. Lloyd, J.M. Molina-Aldareguia, and W.J. Clegg: Deformation under nanoindents in sapphire, spinel and magnesia examined using transmission electron microscopy. Philos. Mag. A. 82, 1963 (2002).

A. Kelly, G.W. Groves, and P. Kidd: Crystallography and Crystal Defects (Wiley, Chichester, 2000).

S. Bouvier and A. Needleman: Effect of the number and orientation of active slip systems on plane strain single crystal indentation. Modell. Simul. Mater. Sci. Eng. 14, 1105 (2006).

J.J. Gilman: Chemistry and Physics of Mechanical Hardness (Wiley, New York, 2009).

S. Korte and W. Clegg: Micropillar compression of ceramics at elevated temperatures. Scr. Mater. 60, 807 (2009).

B. Moser, K. Wasmer, L. Barbieri, and J. Michler: Strength and fracture of Si micropillars: A new scanning electron microscopy-based micro-compression test. J. Mater. Res. 22, 1004 (2007).

J. Deneen Nowak, W.M. Mook, A.M. Minor, W.W. Gerberich, and C.B. Carter: Fracturing a nanoparticle. Philos. Mag. 87, 29 (2007).

J. Deneen, W.M. Mook, A.M. Minor, W.W. Gerberich, and C.B. Carter: In situ deformation of silicon nanospheres. J. Mater. Sci. 41, 4477 (2006).

W.W. Gerberich, W.M. Mook, C.R. Perrey, C.B. Carter, M.I. Baskes, R. Mukherjee, A. Gidwani, J. Heberlein, P.H. McMurry, and S.L. Girshick: Superhard silicon nanospheres. J. Mech. Phys. Solids. 51, 979 (2003).

A.A. Griffith: The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. A. 221, 163 (1921).

C. Gurney and J. Hunt: Quasi-static crack propagation. Proc. Roy. Soc. A. 299, 508 (1967).

K. Kendall: Complexities of compression failure. Proc. Roy. Soc. A. 361, 245 (1978).

K.E. Puttick: The mechanics of indentation fracture in poly (methyl methacrylate). J. Phys. D. 11, 595 (1978).

A.R. Beaber, J.D. Nowak, O. Ugurlu, W.M. Mook, S.L. Girshick, R. Ballarini, and W.W. Gerberich: Smaller is tougher. Philos. Mag. 91, 1179 (2011).

W.W. Gerberich, J. Michler, W.M. Mook, R. Ghisleni, F. Östlund, D.D. Stauffer, and R. Ballarini: Scale effects for strength, ductility, and toughness in “brittle” materials. J. Mater. Res. 24, 899 (2009).

H. Huang and W.W. Gerberich: Crack-tip dislocation emission arrangements for equilibrium–II. Comparisons to analytical and computer simulation models. Acta Metall. Mater. 40, 2873 (1992).

A.H. Cottrell: Theory of brittle fracture in steel and similar metals. Trans. Metall. Soc. AIME. 212, 192 (1958).

J.E. Gordon: The New Science of Strong Materials (Penguin Books, Harlow, 1968).

M.F. Ashby and C.G. Sammis: The damage mechanics of brittle solids in compression. Pure Appl. Geophys. 133, 489 (1990).

B.R. Lawn and T.R. Wilshaw: Fracture of Brittle Solids (Cambridge University Press, Cambridge, 1975).

F. Ericson, S. Johansson, and J-Å. Schweitz: Hardness and fracture toughness of semiconducting materials studied by indentation and erosion techniques. Mater. Sci. Eng., A. 105, 131 (1988).

S. Adachi: Physical Properties of III-V Semiconductor Compounds (Wiley-VCH, New York, 1992).

F. Ericson and J-Å. Schweitz: Micromechanical fracture strength of silicon. J. Appl. Phys. 68, 5840 (2009).

J.J. Wortman and R.A. Evans: Young’s modulus, shear modulus, and Poisson’s ratio in silicon and germanium. J. Appl. Phys. 36, 153 (1965).

R.W. Rice, C.C. Wu, and K.R. McKinney: Fracture and fracture toughness of stoichiometric MgAl2O4 crystals at room temperature. J. Mater. Sci. 31, 1353 (1996).

A.K. Kushwaha: Vibrational and elastic properties of aluminate spinel MgAl2O4. Physica B 405, 2795 (2010).

C.L. Conner and K.T. Faber: Segregant-enhanced fracture in magnesium oxide. J. Mater. Sci. 25, 2737 (1990).

D-H. Chung: Elastic moduli of single crystal and polycrystalline MgO. Philos. Mag. 8, 833 (1963).

K. Hjort, J. Soderkvist, and J-Å. Schweitz: Gallium arsenide as a mechanical material. J. Micromech. Microeng. 4, 1 (1994).

J.L. Beuth: Cracking of thin bonded films in residual tension. Int. J. Solids Struct. 29, 1657 (1992).

T. Çağin, J. Che, M.N. Gardos, A. Fijany, and W.A. Goddard: Simulation and experiments on friction and wear of diamond: A material for MEMS and NEMS application. Nanotechnology 10, 278 (1999).

F.P. Bowden and C.A. Brookes: Frictional anisotropy in nonmetallic crystals. Proc. Roy. Soc. A 295, 244 (1966).

Acknowledgments

The authors acknowledge J. Michler, R. Ghisleni, and W. W. Gerberich for helpful discussions. This work was supported by the Engineering and Physical Sciences Research Council [EP/F033605/1] (PRH) and [EP/C518012/1] (SK).

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

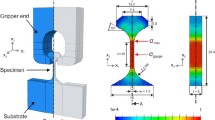

Kendall describes, in terms of global energy changes, the formation of splitting cracks in columns compressed using a punch with a width smaller than that of the column itself.19 Each half-column is then loaded asymmetrically and bends, allowing the compressive force to move downward and do work. In the absence of frictional effects, this driving force goes to zero as the punch width approaches the pillar width. In micropillar compression, where the punch is typically much larger than the pillar top, one might expect no effect. However, an effect arises because the pillar tapers, so that the centroid of each half pillar is closer to the axis at the top of the pillar than it is at the bottom. Kendall’s calculation has been adapted to estimate the magnitude of this effect on the driving force due to through-thickness axial splitting.

Consider the pillar shown in Fig. A1, the centroid of each semicylindrical slice is at a distance y′ from the center of the pillar, where

r is the radius of the pillar at some depth in the pillar and depends on the vertical position within the pillar and on the taper angle, α

where rtop is the radius of the top of the pillar and z is the distance from the top of the pillar. The second moment of area with respect to the centroid axis is

The bending moment in each slice through the pillar is produced by the difference in centroid position

where

The bending strain energy in the two beams taken together is given by

so that the contribution to the driving force from the taper is

where d is taken to be equal to 2rtop. Expressing the stress intensity factor of the crack derived for uniaxial splitting, Equation (2), in terms of a crack driving force gives

The relative value of the two driving forces is therefore given by

Taking typical values for silicon micropillars of β = 1.1, S = 0.47 and φ = 54.7° and taking c = z ≈ 0.7 d at the onset of splitting gives\({{G_{{\rm{taper}}} } \over {G_{{\rm{split}}} }} = 0.06 - 0.22\) for α between 2 and 4°. The additional driving force due to the taper is therefore considered to be a secondary effect, at least where crack nucleation is concerned.

Rights and permissions

About this article

Cite this article

Howie, P.R., Korte, S. & Clegg, W.J. Fracture modes in micropillar compression of brittle crystals. Journal of Materials Research 27, 141–151 (2012). https://doi.org/10.1557/jmr.2011.256

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.256