Abstract

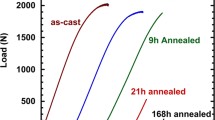

Plasticity in amorphous alloys is associated with strain softening, induced by the creation of additional free volume during deformation. In this paper, the role of free volume, which was a priori in the material, on work softening was investigated. For this, an as-cast Zr-based bulk metallic glass (BMG) was systematically annealed below its glass transition temperature, so as to reduce the free volume content. The bonded-interface indentation technique is used to generate extensively deformed and well defined plastic zones. Nanoindentation was utilized to estimate the hardness of the deformed as well as undeformed regions. The results show that the structural relaxation annealing enhances the hardness and that both the subsurface shear band number density and the plastic zone size decrease with annealing time. The serrations in the nanoindentation load-displacement curves become smoother with structural relaxation. Regardless of the annealing condition, the nanohardness of the deformed regions is ∼12–15% lower, implying that the prior free volume only changes the yield stress (or hardness) but not the relative flow stress (or the extent of strain softening). Statistical distributions of the nanohardness obtained from deformed and undeformed regions have no overlap, suggesting that shear band number density has no influence on the plastic characteristics of the deformed region.

Similar content being viewed by others

References

C.A. Schuh, T.C. Hufnagel, and U. Ramamurty: Mechanical behavior of amorphous alloys. Acta Mater. 55, 4067 (2007).

K.E. Prasad, R. Raghavan, and U. Ramamurty: Temperature dependence of pressure sensitivity in a metallic glass. Scr. Mater. 57, 121 (2007).

M.N.M. Patnaik, R. Narasimhan, and U. Ramamurty: Spherical indentation response of metallic glasses. Acta Mater. 52, 3335 (2007).

P. Tandaiya, R. Narasimhan, and U. Ramamurty: Mode I crack tip fields in amorphous materials with application to metallic glasses. Acta Mater. 55, 6541 (2007).

F. Spaepen: A microscopic mechanism for steady state inhomogeneous flow in metallic glasses. Acta Metall. 25, 407 (1977).

A.S. Argon: Plastic deformation in metallic glasses. Acta Metall. 27, 47 (1979).

C.T. Liu, L. Heatherly, D.S. Easton, C.A. Carmichael, J.H. Schneibel, C.H. Chen, J.L. Wright, M.H. Yoo, J.A. Horton, and A. Inoue: Test environments and mechanical properties of Zr-base bulk amorphous alloys. Metall. Mater. Trans. A 29, 1811 (1998).

M. Lind, G. Duan, and W.L. Johnson: Isoconfigurational elastic constants and liquid fragility of a bulk metallic glass forming alloy. Phys. Rev. Lett. 97, 015501 (2006).

T. Egami: Formation and deformation of metallic glasses: Atom-istic theory. Intermetallics 14, 882 (2006).

K-W. Park, J-I. Jang, M. Wakeda, Y. Shibutani, and J-C. Lee: Atomic packing density and its influence on the properties of Cu-Zr amorphous alloys. Scr. Mater. 57, 805 (2007).

C. Nagel, K. Ratzke, E. Schmidtke, J. Wolfe, U. Geyer, and F. Faupel: Free-volume changes in the bulk metallic glass Zr46.7Ti8.3Cu7.5Ni10Be27.5 and the undercooled liquid. Phys. Rev. B 57, 10224 (1998).

P. Tuinstra, P.A. Duine, J. Sietsma, and A. Vandenbeukel: The calorimetric glass-transition of amorphous Pd40Ni40P20. Acta Metall. Mater. 43, 2815 (1995).

O.P. Bobrov, V.A. Khonik, S.N. Laptev, and M.Y. Yazvitsky: Comparative internal friction study of bulk and ribbon glassy Zr52.5Ti5Cu17.9Ni14.6Al10. Scr. Mater. 49, 255 (2003).

A. Slipenyuk and J. Eckert: Correlation between enthalpy change and free volume reduction during structural relaxation of Zr55Cu30Al10Ni5 metallic glass. Scr. Mater. 50, 39 (2004).

W. Dmowski, C. Fan, M.L. Morrison, P.K. Liaw, and T. Egami: Structural changes in bulk metallic glass after annealing below the glass-transition temperature. Mater. Sci. Eng., A 471, 125 (2007).

U. Ramamurty, M.L. Lee, J. Basu, and Y. Li: Embrittlement of a bulk metallic glass due to low-temperature annealing. Scr. Mater. 47, 107 (2002).

P. Murali and U. Ramamurty: Embrittlement of a bulk metallic glass due to sub-Tg annealing. Acta Mater. 53, 1467 (2005).

R. Raghavan, P. Murali, and U. Ramamurty: Ductile to brittle transition in the Zr41.2Ti13.75Cu12.5Ni10Be22.5 bulk metallic glass. Intermetallics 14, 1051 (2006).

H.W. Jin, R. Ayer, J.Y. Koo, R. Raghavan, and U. Ramamurty: Reciprocating wear mechanisms in a Zr-based bulk metallic glass. J. Mater. Res. 22, 264 (2007).

M.E. Launey, R. Busch, and J.J. Kruzic: Effects of free volume changes and residual stresses on the fatigue and fracture behavior of a Zr-Ti-Ni-Cu-Be bulk metallic glass. Acta Mater. 56, 500 (2008).

W.H. Jiang, F.E. Pinkerton, and M. Atzmon: Mechanical behavior of shear bands and the effect of their relaxation in a rolled amorphous Al-based alloy. Acta Mater. 53, 3469 (2005).

W.H. Wang, C. Dong, and C.H. Shek: Bulk metallic glasses. Mater. Sci. Eng., R 44, 45 (2004).

A.R. Yavari, J.J. Lewandowski, and J. Eckert: Mechanical properties of bulk metallic glasses. MRS Bull. 32, 635 (2007).

C.A. Schuh and T.G. Nieh: A survey of instrumented indentation studies on metallic glasses. J. Mater. Res. 19, 46 (2004).

R. Bhowmick, R. Raghavan, K. Chattopadhyay, and U. Ramamurty: Plastic flow softening in a bulk metallic glass. Acta Mater. 54, 4221 (2006).

U. Ramamurty, S. Jana, Y. Kawamura, and K. Chattopadhyay: Hardness and plastic deformation in a bulk metallic glass. Acta Mater. 53, 705 (2005).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

D. Suh and R.H. Dauskardt: Flow and fracture in Zr-based bulk metallic glasses. Ann. Chim.–Sci. Mat. 27, 25 (2002).

R. Bohmer, K.L. Ngai, C.A. Angell, and D.J. Plazek: Nonexperimential relaxations in strong and fragile glass formers. J. Chem. Phys. 99, 4201 (1993).

R. Raghavan, P. Murali, and U. Ramamurty: Influence of cooling rate on the enthalpy relaxation and fragility of a metallic glass. Metall. Mater. Trans. A 39, 1573 (2008).

K.L. Johnson: Contact Mechanics, 1st ed. (Cambridge University Press, Cambridge, UK, 1985).

C.A. Schuh and T.G. Nieh: A nanoindentation study of serrated flow in bulk metallic glasses. Acta Mater. 51, 87 (2003).

W.H. Jiang and M. Atzmon: Rate dependence of serrated flow in a metallic glass. J. Mater. Res. 18, 755 (2003).

A.L. Greer, A. Castellero, S.V. Madge, I.T. Walker, and J.R. Wilde: Nanoindentation studies of shear banding in fully amorphous and partially devitrified metallic alloys. Mater. Sci. Eng., A 375–377, 1182 (2004).

C.A. Schuh, A.C. Lund, and T.G. Nieh: New regime of homogeneous flow in the deformation map of metallic glasses: Elevated temperature nanoindentation experiments and mechanistic modeling. Acta Mater. 52, 5879 (2004).

B.C. Wei, L.C. Zhang, T.H. Zhang, D.M. Xing, J. Das, and J. Eckert: Strain rate dependence of plastic flow in Ce-based bulk metallic glass during nanoindentation. J. Mater. Res. 22, 258 (2007).

B. Yang and T.G. Nieh: Effect of the nanoindentation rate on the shear band formation in an Au-based bulk metallic glass. Acta Mater. 55, 295 (2007).

J-I. Jang, M.J. Lance, S. Wen, and G.M. Pharr: Evidence for nanoindentation-induced phase transformations in germanium. Appl. Phys. Lett. 86, 131907 (2005).

J-I. Jang and G.M. Pharr: Influence of indenter angle on cracking in Si and Ge during nanoindentation. Acta Mater. 56, 4458 (2008).

J-I. Jang, B-G. Yoo, and J-Y. Kim: Rate-dependent inhomogeneous-to-homogeneous transition of plastic flows during nanoindentation of bulk metallic glasses: Fact or artifact? Appl. Phys. Lett. 90, 211906 (2007).

B-G. Yoo, J-Y. Kim, and J-I. Jang: Influence of indenter geometry on the deformation behavior of Zr60Cu30A110 bulk metallic glass during nanoindentation. Mater. Trans. 48, 1765 (2007).

L. Wang, S.X. Song, and T.G. Nieh: Assessing plastic shear resistance of bulk metallic glasses under nanoindentation. Appl. Phys. Lett. 92, 101925 (2008).

H. Bei, S. Xie, and E.P. George: Softening caused by profuse shear banding in a bulk metallic glass. Phys. Rev. Lett. 96, 105503 (2006).

S. Xie and E.P. George: Hardness and shear band evolution in bulk metallic glasses after plastic deformation and annealing. Acta Mater. 56, 5202 (2008).

B-G. Yoo and J-I. Jang: A study on the evolution of subsurface deformation in a Zr-based bulk metallic glass during spherical indentation. J. Phys. D: Appl. Phys. 41, 074017 (2008).

C. Tang, Y. Li, and K. Zeng: Characterization of mechanical properties of a Zr-based metallic glass by indentation techniques. Mater. Sci. Eng., A 384, 215 (2004).

W.H. Li, T.H. Zhang, D.M. Xing, B.C. Wei, Y.R. Wang, and Y.D. Dong: Instrumented indentation study of plastic deformation in bulk metallic glasses. J. Mater. Res. 21, 75 (2006).

D. Tabor: Hardness of Metals, 1st ed. (Clarendon Press, Oxford, UK, 1951).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoo, BG., Park, KW., Lee, JC. et al. Role of free volume in strain softening of as-cast and annealed bulk metallic glass. Journal of Materials Research 24, 1405–1416 (2009). https://doi.org/10.1557/jmr.2009.0167

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0167