Abstract

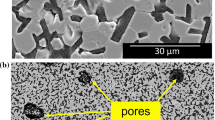

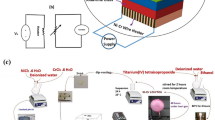

The structure evolution and oxidation behavior of ZrB2–SiC composites in air from room temperature to ultrahigh temperature were investigated using furnace testing, arc jet testing, and thermal gravimetric analysis (TGA). The oxide structure changed with the increasing temperature. SiC content has no apparent influence on the evolution of structure during the oxidation of ZrB2–SiC below 1600 °C. However, the evolution of structure for ZrB2–SiC above 1800 °C was significantly affected by the SiC content. The formation of the SiC depleted layer in the ZrB2–SiC system not only depends on the surrounding conditions of pressure and temperature but also on the structure distribution of the SiC in the ZrB2 matrix. The apparent recrystallization of the ZrO2 occurred above 1800 °C. The SiC content should be controlled at ∼16% in the ZrB2–SiC system for the ultrahigh-temperature application. The mechanisms of the structure evolution during oxidation in air were also analyzed.

Similar content being viewed by others

References

K. Upadhya, J.M. Yang W.P. Hoffman: Materials for ultrahigh temperature structural applications. Am. Ceram. Soc. Bull. 76, 51 1997

S.R. Levine, E.J. Opila, M.C. Halbig, J.D. Kiser, M. Singh J.A. Salem: Evaluation of ultra-high temperature ceramics for aeropropulsion use. J. Eur. Ceram. Soc. 22, 2757 2002

E. Wuchina, M. Opeka, S. Causey, K. Buesking, J. Spain, A. Cull, J. Routbort F. Guitierrez-Mora: Designing for ultra high temperature applications: The mechanical and thermal properties of HfB2, HfCx, HfNx, and Hf(N). J. Mater. Sci. 39, 5939 2004

D.M. Van Wie, D.G. Drewry Jr., D.E. King C.M. Hudson: The hypersonic environment: Required operating conditions and design challenges. J. Mater. Sci. 39, 5915 2004

F. Monteverde: The thermal stability in air of hot-pressed diboride matrix composites for uses at ultra-high temperatures. Corros. Sci. 47, 2020 2005

M. Gasch, D. Ellerby, E. Irby, S. Beckman, M. Gusman S. Johnson: Processing, properties and arc jet oxidation of hafnium diboride/Silicon carbide ultra high temperature ceramic. J. Mater. Sci. 39, 5925 2004

F. Monteverde A. Bellosi: Microstructure and properties of an HfB2–SiC composite for ultra high temperature applications. Adv. Eng. Mater. 6, 331 2004

F. Monteverde A. Bellosi: The resistance to oxidation of an HfB2–SiC composite. J. Eur. Ceram. Soc. 25, 1025 2005

A.L. Chamberlain, W.G. Fahrenholtz G.E. Hilmas: Oxidation of ZrB2–SiC ceramics under atmospheric and reentry conditions. Refract. Appl. Trans. 1, 1 2005

M.M. Opeka, I.G. Talmy J.A. Zaykoski: Oxidation-based materials selection for 2000 °C + hypersonic aerosurfaces: Theoretical considerations and historical experience. J. Mater. Sci. 39, 5887 2004

F. Monteverde A. Bellosi: Oxidation of ZrB2-based ceramics in dry air. J. Electrochem. Soc. 150, 552 2003

W.G. Fahrenholtz, G.E. Hilmas, A.L. Chamberlain J.W. Zimmermann: Processing and characterization of ZrB2-based ultra-high temperature monolithic and fibrous monolithic ceramics. J. Mater. Sci. 39, 5951 2004

W.G. Fahrenholtz, G.E. Hilmas, I.G. Talmy J.A. Zaykoski: Refractory diborides of zirconium and hafnium. J. Am. Ceram. Soc 90, 1347 2007

J.C. Han, P. Hu, X.H. Zhang S.H. Meng: Oxidation behavior of zirconium diboride-silicon carbide at 1800 °C. Scr. Mater. 57, 825 2007

J.C. Han, P. Hu, X.H. Zhang, S.H. Meng W.B. Han: Oxidation resistant ZrB2–SiC composites at 2200 °C. Compos. Sci. Technol. 68, 799 2008

X.H. Zhang, P. Hu, J.C. Han S.H. Meng: Ablation behavior of ZrB2–SiC ultra high temperature ceramics under simulated atmospheric re-entry conditions. Compos. Sci. Technol. 68, 1718 2008

W.G. Fahrenholtz: Thermodynamic analysis of ZrB2–SiC oxidation: Formation of a SiC-depletion region. J. Am. Ceram. Soc. 90, 143 2007

A. Rezaie, W.G. Fahrenholtz G.E. Hilmas: Evolution of structure during the oxidation of zirconium diboride-silicon carbide in air up to 1500 °C. J. Eur. Ceram. Soc. 27, 2495 2007

W.G. Fahrenholtz: The ZrB2 volatility diagram. J. Am. Ceram. Soc. 88, 3509 2005

A.L. Chamberlain, W.G. Fahrenholtz, G.E. Hilmas D.T. Ellerby: Characterization of zirconium diboride-molybdenum disilicide ceramics. Ceram. Trans. 153, 299 2004

D. Sciti, M. Brach A. Bellosi: Oxidation behavior of a pressureless sintered ZrB2–MoSi2 ceramic composite. J. Mater. Res. 20, 922 2005

E.J. Opila, S.R. Levine J. Lorincz: Oxidation of ZrB2- and HfB2-based ultra-high temperature ceramics: Effect of Ta additions. J. Mater. Sci. 39, 5969 2004

I.G. Talmy, J.A. Zaykoski, M.M. Opeka A.H. Smith: Properties of ceramics in the system ZrB2–Ta5Si3. J. Mater. Res. 21, 2593 2006

S.R. Levine E.J. Opila: Tantalum addition to zirconium diboride for improved oxidation resistance. NASA/TM—2003-212483, 2003 1–13

V.A. Lavrenko, A.D. Panasyuk, T.G. Protsenko, V.P. Dyatel, E.S. Lugovskaya E.I. Egorova: High temperature reactions of materials of the ZrB2–ZrSi2 system with oxygen. Poroshk. Metall. 6, 56 1981

I.G. Talmy, J.A. Zaykoski, M.M. Opeka S. Dallek: Oxidation of ZrB2 ceramics modified with SiC and group IV-VI transition netal borides in High Temperature Corrosion and Materials Chemistry III edited by M. McNallan and E. Opila The Electrochemical Society Pennington, NJ, 2001 144–153

T. Goto H. Homma: High-temperature active/passive oxidation and bubble formation of CVD SiC in O2 and CO2 atmospheres. J. Eur. Ceram. Soc. 22, 2749 2002

M.J.H. Balat: Determination of the active-to-passive transition in the oxidation of silicon carbide in standard and microwave-excited air. J. Eur. Ceram. Soc. 16, 55 1996

M.W. Chase Jr.: NIST-JANAF Thermochemical Tables 4th ed. American Institute of Physics Woodbury, NY 1998

A.H. Heuer V.L.K. Lou: Volatility diagrams for silica, silicon nitride, and silicon carbide and their application to high-temperature decomposition and oxidation. J. Am. Ceram. Soc. 73, 2786 1990

Acknowledgments

This work was supported by the National Natural Science Foundation of China (50602010), the Research Fund for the Doctoral Program of Higher Education (20060213031), and the Program for New Century Excellent Talents in University.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, XH., Hu, P. & Han, JC. Structure evolution of ZrB2–SiC during the oxidation in air. Journal of Materials Research 23, 1961–1972 (2008). https://doi.org/10.1557/JMR.2008.0251

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2008.0251