Abstract

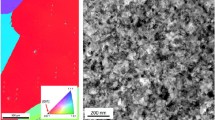

Young’s moduli of nanocrystalline Fe, Cu, Ni, and Cu-Ni alloys prepared by mechanical milling/alloying have been measured by the nanoindentation technique. The results indicate that Young’s moduli of nanocrystalline Cu, Ni, and Cu–Ni alloys with a grain size ranging from 17 to 26 nm are similar to those of the corresponding polycrystals. The dependence of Young’s modulus of nanocrystalline Fe on grain size corresponds well to a theoretical prediction, which suggests that the change in the Young and shear moduli of nanocrystalline materials, free of porosity, with a grain size larger than about 4 nm, should be very limited (<10%). It is likely that reported large decreases in the Young and shear moduli of nanocrystalline materials prepared by gas-condensation/vacuum consolidation result from a relatively large volume fraction of pores.

Similar content being viewed by others

References

H. Gleiter, Prog. Mater. Sci. 33, 223 (1989).

H. Gleiter, in Mechanical Properties and Deformation Behavior of Materials Having Ultra-Fine Microstructures, edited by M. Nastasi, D. M. Parkin, and H. Gleiter (Kluwer Academic Publishers, Dordrecht/Boston/London, 1993), NATO ASI Series, Series E: Applied Sciences, Vol. 233, p. 1.

A. L. Greer, ibid, p. 53.

K. T. Aust, U. Erb, and G. Palumbo, ibid, p. 107.

J. D. Embury and D. J. Lahaie, ibid, p. 287.

R. W. Siegel, ibid, p. 509.

V. G. Gryaznov and L. I. Trusov, Prog. Mater. Sci. 37, 289 (1993).

G. D. Hughes, S. D. Smith, C. S. Pande, H. R. Johnson, and R. W. Armstrong, Scripta Metall. 20, 93 (1986).

J. S. C. Jang and C. C. Koch, Scripta Metall Mater. 24, 1599 (1990).

G. W. Nieman, J. R. Weertman, and R. W. Siegel, Scripta Metall. Mater. 24, 145 (1990).

G. W. Nieman, J. R. Weertman, and R. W. Siegel, J. Mater. Res. 6, 1012 (1991).

G. W. Nieman, J. R. Weertman, and R. W. Siegel, in Clusters and Cluster-Assembled Materials, edited by R. R. Averback, J. Bernholc, and D. L. Nelson (Mater. Res. Soc. Symp. Proc. 206, Pittsburgh, PA, 1991), p. 493.

K. Y. Wang, T. D. Shen, M. X. Quan, and W. D. Wei, J. Mater. Sci. Lett. 12, 1818 (1993).

J. S. C. Jang and C. C. Koch, Scripta Metall. 22, 677 (1988).

G. McMahon and U. Erb, Microstruc. Sci. 17, 447 (1989).

Y. S. Cho and C. C. Koch, Mater. Sci. Eng. A 141, 139 (1991).

H. Chang, C. J. Alstetter, and R. S. Averback, J. Mater. Res. 7, 2692 (1992).

D. K. Kim and K. Okazaki, Mater. Sci. Forum 88–90, 553 (1992).

H. Y. Tong, J. T. Wang, B. Z. Ding, H. G. Jiang, and K. Lu, J. Non-Cryst. Solids 150, 444 (1992).

X. D. Liu, Z. Q. Hu, and B. Z. Ding, NanoStru. Mater. 2, 545 (1993).

T. Tsakalakos and J. E. Hilliard, J. Appl. Phys. 54, 734 (1983).

D. Baral, J. B. Ketterson, and J. E. Hilliard, J. Appl. Phys. 57, 1076 (1985).

W. M. C. Yang, T. Tsakalakos, and J. E. Hilliard, J. Appl. Phys. 48, 876 (1977).

G. Henein and J. E. Hilliard, J. Appl. Phys. 54, 728 (1983).

A. Fartash, E. E. Fullerton, I. K. Schuller, S. E. Bobbin, J. W. Wagner, R. C. Cammarata, S. Kumar, and M. Grimsditch, Phys. Rev. B 44, 13 760 (1991–11).

R. C. Cammarata, T. E. Schlesinger, C. Kim, S. B. Qadri, and A. E. Edelstein, Appl. Phys. Lett. 56, 1862 (1990).

A. Moreau, J. B. Ketterson, and J. Mattson, Appl. Phys. Lett. 56, 1959 (1990).

J. W. Mintmire, Mater. Sci. Eng. A 126, 29 (1990).

B. M. Davis, D. N. Seidman, A. Moreau, J. B. Ketterson, J. Mattson, and M. Grimsditch, Phys. Rev. B 43, 9304 (1991–11).

Y. Sasajima, S. Taya, and R. Yamamoto, J. Magn. Magn. Mater. 126, 218 (1993).

M. Weiler, J. Diehl, and H-E. Schaffer, Philos. Mag. 63, 527 (1991).

D. Korn, A. Morsch, R. Birringer, W. Arnold, and H. Gleiter, J. Phys. (Paris) 49, c5-375 (1988).

M. J. Mayo, R. W. Siegel, A. Narayanasamy, and W. D. Nix, J. Mater. Res. 5, 1073 (1990).

V. Krstic, U. Erb, and G. Palumbo, Scripta Metall. Mater. 29, 1501 (1993).

N. Karpe, G. Lapogian, J. Bøttiger, and J. P. Krog, Philos. Mag. B 71, 445 (1995).

C. C. Koch, NanoStru. Mater. 2, 109 (1993).

T. D. Shen and C. C. Koch, Mater. Sci. Forum 179–181, 17 (1995).

W. C. Oliver and G. M. Pharr, J. Mater. Res. 7, 1564 (1992).

G. K. Williamson and W. H. Hall, Acta Metall. 1, 22 (1953).

A. Wolfenden, Dynamic Elastic Modulus Measurements in Materials (ASTM, Philadelphia, PA, 1990), p. 135.

Metals Handbook, 10th ed., Vol. 2, Properties and Selection—Nonferrous Alloys and Special-Purpose Materials (ASM INTERNATIONAL, Materials Park, OH, 1990), pp. 265, 338, 437.

A. K. Giri, Mater. Lett. 17, 353 (1993).

R. Boyer, G. Welsch, and E. W. Collings, Materials Properties Handbook: Titanium Alloys (ASM INTERNATIONAL, Materials Park, OH, 1994), p. 94.

G. Palumbo, S. J. Thorpe, and K. T. Aust, Scripta Metall. Mater. 24, 1347 (1990).

L. Wong, D. Ostrandeer, U. Erb, G. Palumbo, and K. T. Aust, in Nanophases and Nanocrystalline Structures, edited by R. D. Shull and J. M. Sanchez (The Minerals, Metals & Materials Society, Warrendale, PA, 1994), p. 85.

T. Masumoto and R. Maddin, Mater. Sci. Eng. 19, 1 (1975).

M. D. Kluge, D. Wolf, J. F. Lutsko, and S. R. Phillpot, J. Appl. Phys. 67, 2370 (1990).

B. Paul, Trans. AIME 218, 36 (1960).

Da Chen, Mater. Sci. Eng. A 190, 193 (1995).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Shen, T.D., Koch, C.C., Tsui, T.Y. et al. On the elastic moduli of nanocrystalline Fe, Cu, Ni, and Cu–Ni alloys prepared by mechanical milling/alloying. Journal of Materials Research 10, 2892–2896 (1995). https://doi.org/10.1557/JMR.1995.2892

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1995.2892