Abstract

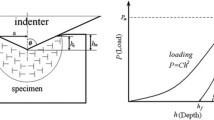

The role of friction between the microhardness indenter and the test specimen is addressed through the analysis of dry (unlubricated) and lubricated tests on iron by Atkinson and Shi. Quantitative evaluation through a proportional specimen resistance model accurately describes the results. It suggests that friction is a major portion of the observed hardness increase at low test loads, the indentation size effect. The ISE is related to the surface-area-to-volume ratio of the indentation, which is inversely related to the indentation dimension.

Similar content being viewed by others

References

E.O. Bernhardt J. Metall. 33, 135 (1941).

P.M. Sargent and T.F. Page Proc. Br. Ceram. Soc. 26, 209 (1978).

P. M. Sargent ASTM STP 889, 160 (1984).

P. N. Kotru A. K. Razdan and B. M. Wanklyn J. Mater. Sci. 24, 793 (1989).

H. Li and R. C. Bradt Mater. Sci. Eng. A142, 51 (1991).

D. R. Tate Trans. Am. Soc. Met. 35, 374 (1945).

C. Hays and E. G. Kendall Metall. 6, 275 (1973).

S.A. Varchenya F. O. Muktepavel and G.P. Upit Sov. Phys. Solid State 11, 2300 (1970).

N. Gane and J. M. Cox Philos. Mag. 22, 881 (1970).

S.J. Bull T.F. Page and E.H. Yoffe Philos. Mag. Lett. 59, 281 (1989).

U.K . Hirao and M. Tomozawa J. Am. Ceram. Soc. 70, 497 (1987).

F. G. Yost Metall. Trans. 14A, 947 (1983).

H. Li and R. C. Bradt (accepted by J. Mater. Sci.) (1992).

H. Li and R. C. Bradt in Ceramics Toward the 21st Century, edited by N. Soga and A. Kato Proc. Jpn. Int. Cent. Symp., Tokyo (1991), p. 324.

M. Atkinson and H. Shi Mater. Sci. Technol. 5, 613 (1989).

H. Shi and M. Atkinson J. Mater. Sci. 25, 2111 (1990).

M. Atkinson J. Testing and Eval. 19, 368 (1991).

H. Li and R.C. Bradt J. Non-Cryst. Solids 146, 197 (1992).

C. Rubenstein Trans. ASME 1. Appl. Mech. 48, 796 (1981).

G. M. Pharr and R. F. Cook J. Mater. Res. 5, 847 (1990).

B.D. Michaels and G.H. Frischat J. Mater. Sci. 17, 329 (1982).

F. Frohlich P. Gray and W. Grehlman Phys. Status Solidi 42, 79 (1977).

M.F. Doerner and W. D. Nix J. Mater. Res. 1, 601 (1986).

J. B. Pethica R. Hutchings and W. C. Oliver Philos. Mag. 48, 593 (1983).

G.M. Pharr and W. C. Oliver J. Mater. Res. 4, 94 (1989).

J. B. Pethica and W. C. Oliver Phys. Scripta T19, 61 (1987).

C.W. Shih M. Yang and J.C.M. Li J. Mater. Res. 6, 2623 (1991).

E. E. Grazda and M. Brenner in Handbook of Applied Mathematics (D. Van Nostrand, New York, 1961), pp. 123 and 647.

R.F. Bishop R. Hill and N.F. Mott Proc. Phys. Soc. 57, 147 (1945).

D. S. Dugdale J. Mech. and Phys. Solids 3, 206 (1955).

J.B. Haddlow and W. Johnson Int. J. Mech. Sci. 3, 229 (1961).

R. Beemkwer R. Chait and H. H. Lin in Science of Hardness Testing, edited by J. W. Westbrook and H. Conrad (ASM, Metals Park, OH, 1973), p. 75.

R. E. Hanneman and J. H. Westbrook Philos. Mag. 18, 73 (1968).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Li, H., Ghosh, A., Han, Y.H. et al. The frictional component of the indentation size effect in low load microhardness testing. Journal of Materials Research 8, 1028–1032 (1993). https://doi.org/10.1557/JMR.1993.1028

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1993.1028