Article contents

The role of temperature in the strengthening of Cu–Al alloys processed by surface mechanical attrition treatment

Published online by Cambridge University Press: 04 May 2015

Abstract

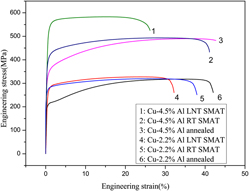

In the present work, Cu–Al alloys were processed by surface mechanical attrition treatment (SMAT) under both room and liquid nitrogen temperature (LNT) conditions. In contrast to room temperature (RT) SMAT, dynamic recovery and recrystallization were largely suppressed during the LNT process. A gradient microstructure was obtained due to the gradient strain and strain rate impacted onto the sample. Microhardness measurement showed that the hardness values gradually decreased from the top surface to the central region. The local hardness of the top surface layer of the LNT and RT SMAT Cu–4.5% Al samples reached maximum values of 1.52 and 1.28 GPa, respectively. The Cu–4.5% Al alloy exhibited an improved yield strength of ∼496 MPa and a higher ductility (compared with literature data of Cu–Al alloys synthesized traditional severe plastic deformation methods) of 15.4% after the LNT SMAT process. A brittle-ductile failure pattern was easily distinguished after fracture. Moreover, the LNT SMAT is a low-cost process with high productivity and can be applied to various types of metallic production.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 3

- Cited by