No CrossRef data available.

Article contents

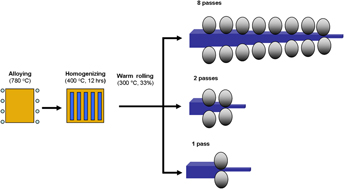

Microstructure and texture evolution in Mg–Al–Zn–(AgIn) alloy during single and multiple pass warm rolling

Published online by Cambridge University Press: 17 March 2015

Abstract

The present research is focused on studying the evolution of microstructure and texture of a magnesium based alloy with the target composition Mg–3Al–1Zn–(0.5AgIn). Three samples A, B, and C were warm rolled at 300 °C to a cumulative reduction of 33% in 1, 2, and 8 passes, respectively. The optical microstructures and scanning electron microscopy (SEM) results revealed that sample A possessed more dynamic recrystallization (DRX) as compared to samples B and C. A split of basal pole from normal direction (ND) toward transverse direction (TD) was observed for sample A. However, as the number of passes was increased, the basal pole split was converted into a single peak for samples B and C. The basal intensity of sample C became almost double than that of sample A. It was concluded that a higher reduction per pass resulted in a larger volume fraction of DRXed grains and a weaker basal texture.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015