Article contents

Highly improving the electrochemical performance of LiFePO4 modified by metal phthalocyanines as cathode materials

Published online by Cambridge University Press: 18 February 2015

Abstract

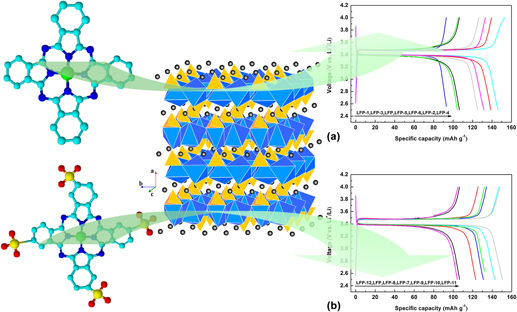

Two novel series of cathode materials LiFe1−xMxPO4/C (x ≈ 0.0040; M = Mn, Fe, Co, Ni, Cu, and Zn) composites based on metal phthalocyanines (MPc) and metal tetrasulfophthalocyanines (MPcTs) to modify lithium iron phosphate (LiFePO4) for lithium-ion batteries (LIBs) are in situ prepared by solvothermal and calcination techniques. Structures and morphologies of all the composites are characterized by normal methods. To evaluate the electrochemical performance of the composites, the charge/discharge capabilities, rate performance, cycling stabilities, cyclic voltammetry profiles, and electrochemical impedance spectroscopy plots of the LIBs using them as cathode materials are measured carefully. The results indicate that most of the composites deliver highly improved initial discharge capacity and show remarkable reversibility and cycling stabilities. Especially, composites using MPcTs as additives are more efficient for the improvement of specific capacity, rate capability, reversibility, and cycling stability.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 8

- Cited by