Article contents

Planarized arrays of aligned, untangled multiwall carbon nanotubes with Ohmic back contacts

Published online by Cambridge University Press: 26 November 2014

Abstract

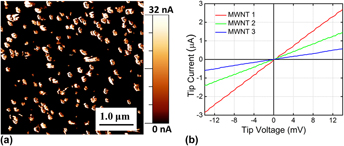

Vertically aligned, untangled planarized arrays of multiwall carbon nanotubes (MWNTs) with Ohmic back contacts were grown in nanopore templates on arbitrary substrates. The templates were prepared by sputter depositing Nd-doped Al films onto W-coated substrates, followed by anodization to form an aluminum oxide nanopore array. The W underlayer helps eliminate the aluminum oxide barrier that typically occurs at the nanopore bottoms by instead forming a thin WO3 layer. The WO3 can be selectively etched to enable electrodeposition of Co catalysts with control over the Co site density. This led to control of the site density of MWNTs grown by thermal chemical vapor deposition, with W also serving as a back electrical contact. Ohmic contact to MWNTs was confirmed, even following ultrasonic cutting of the entire array to a uniform height.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 5

- Cited by