Article contents

Experimental phase diagram of SiC in CH3SiCl3–Ar–H2 system produced by fluidized bed chemical vapor deposition and its nuclear applications

Published online by Cambridge University Press: 05 August 2016

Abstract

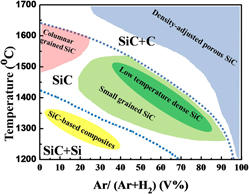

A systematic study of SiC layer preparation in CH3SiCl3–Ar–H2 system by fluidized bed chemical vapor deposition was given. The phase, morphology, grain size, and crystal structure of the products were investigated based on series characterizations methods. Free silicon was formed at lower temperatures while free carbon was formed at higher temperatures. By introducing argon in the deposition system, silicon formation was suppressed and cauliflower structure with subordinate small particles was observed. The formation mechanisms of different microstructures were discussed. The experimental phase diagram of CVD SiC composed of three regions of SiC + Si, SiC and SiC + C was established and boundaries of the three regions were given. The phase diagram obtained can be used to guide the new applications of SiC series materials. The low-temperature dense SiC, porous SiC with tunable densities, small grained SiC, and composite SiC materials were prepared successfully, also it was indicated that SiC jointing technology can be developed based on the phase diagram accordingly in the future.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 10

- Cited by