Article contents

Effect of ultraviolet-irradiation on peeling-induced formation of surface gratings on PMMA films

Published online by Cambridge University Press: 09 June 2016

Abstract

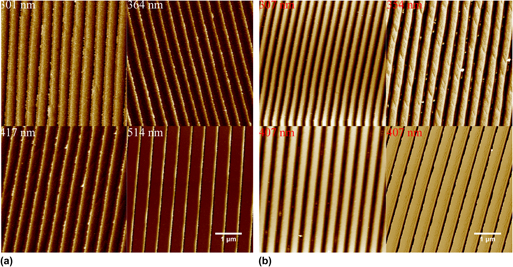

Using the peeling-induced splitting method, the effect of the irradiation of ultraviolet (UV) light on the formation of surface gratings on the surface of PMMA(Poly(Methyl Methacrylate))-based films is investigated at room temperature. The thickness of the PMMA-based films is in range of 236–534 nm, and the irradiation dose is in range of 0–5 J/cm2. Surface gratings are formed on the surface of the irradiated PMMA-based films. The spatial wave length is a linear function of the film thickness, independent of the UV doses used. The peeling-induced splitting process introduces compressive stress on the surface of the PMMA-based films, much larger than the corresponding surface energy. The magnitude of the apparent surface force increases with the increase of the film thickness. All the surface gratings formed have amplitudes approximately in the same range.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

Footnotes

Contributing Editor: Franz Faupel

References

REFERENCES

- 2

- Cited by