Article contents

Local-structure-affected behavior during self-driven grain boundary migration

Published online by Cambridge University Press: 09 March 2016

Abstract

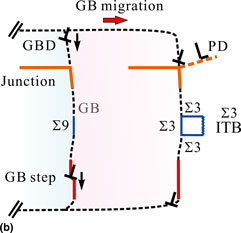

In nanocrystalline (nc) metals, it is still not clear how local grain boundary (GB) structures accommodate GB migration at atomic scales and what dominates the motion of atoms at the inherently unstable GB front. Here, we report the adjustment of the local GB structures at atomic scales during self-driven GB migration, simultaneously involving GB dissociation, partial dislocation emission from GB, and faceting/defaceting in the nc Cu. Furthermore, we reveal that the fundamental of GB migration ability is closely related to the local structure, i.e. the GB segment consisting of “hybrid” structural units and delocalized GB dislocations is relatively unstable.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

- 8

- Cited by