Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

An, Boxing

Ma, Ying

Li, Wenbo

Su, Meng

Li, Fengyu

and

Song, Yanlin

2016.

Three-dimensional multi-recognition flexible wearable sensor via graphene aerogel printing.

Chemical Communications,

Vol. 52,

Issue. 73,

p.

10948.

Kang, Subin

Lee, Jaehong

Lee, Sanggeun

Kim, SeulGee

Kim, Jae‐Kang

Algadi, Hassan

Al‐Sayari, Saleh

Kim, Dae‐Eun

Kim, DaeEun

and

Lee, Taeyoon

2016.

Highly Sensitive Pressure Sensor Based on Bioinspired Porous Structure for Real‐Time Tactile Sensing.

Advanced Electronic Materials,

Vol. 2,

Issue. 12,

Gong, Jianliang

Xu, Bingang

and

Tao, Xiaoming

2017.

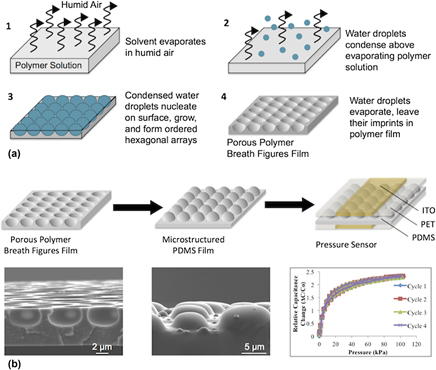

Breath Figure Micromolding Approach for Regulating the Microstructures of Polymeric Films for Triboelectric Nanogenerators.

ACS Applied Materials & Interfaces,

Vol. 9,

Issue. 5,

p.

4988.

Chhetry, Ashok

Yoon, Hyosang

and

Park, Jae Yeong

2017.

A flexible and highly sensitive capacitive pressure sensor based on conductive fibers with a microporous dielectric for wearable electronics.

Journal of Materials Chemistry C,

Vol. 5,

Issue. 38,

p.

10068.

Zhang, Yuan

Hu, Yougen

Zhao, Tao

Zhu, Pengli

Sun, Rong

and

Wong, Chingping

2017.

Highly sensitive flexible pressure sensor based on microstructured PDMS for wearable electronics application.

p.

853.

Fernandes, Jayer

and

Jiang, Hongrui

2017.

Three-Axis Capacitive Touch-Force Sensor for Clinical Breast Examination Simulators.

IEEE Sensors Journal,

Vol. 17,

Issue. 22,

p.

7231.

Chen, Shuwen

Wu, Nan

Ma, Long

Lin, Shizhe

Yuan, Fang

Xu, Zisheng

Li, Wenbo

Wang, Bo

and

Zhou, Jun

2018.

Noncontact Heartbeat and Respiration Monitoring Based on a Hollow Microstructured Self-Powered Pressure Sensor.

ACS Applied Materials & Interfaces,

Vol. 10,

Issue. 4,

p.

3660.

He, Zhongfu

Chen, Wenjun

Liang, Binghao

Liu, Changyong

Yang, Leilei

Lu, Dongwei

Mo, Zichao

Zhu, Hai

Tang, Zikang

and

Gui, Xuchun

2018.

Capacitive Pressure Sensor with High Sensitivity and Fast Response to Dynamic Interaction Based on Graphene and Porous Nylon Networks.

ACS Applied Materials & Interfaces,

Vol. 10,

Issue. 15,

p.

12816.

Kim, Ji-Hye

Lee, Tae-Ik

Kim, Taek-Soo

and

Paik, Kyung-Wook

2018.

Effects of ACFs Modulus and Adhesion Strength on the Bending Reliability of CIF (Chip-in-Flex) Packages at Humid Environment.

p.

2319.

Li, Qi

Duan, Tiantian

Shao, Jian

and

Yu, Hongbin

2018.

Fabrication method for structured porous polydimethylsiloxane (PDMS).

Journal of Materials Science,

Vol. 53,

Issue. 16,

p.

11873.

Yeh

Wu

Huang

Lee

and

Jeng

2019.

In Search of a Green Process: Polymeric Films with Ordered Arrays via a Water Droplet Technique.

Polymers,

Vol. 11,

Issue. 9,

p.

1473.

Pignanelli, Julia

Schlingman, Kory

Carmichael, Tricia Breen

Rondeau-Gagné, Simon

and

Ahamed, Mohammed Jalal

2019.

A comparative analysis of capacitive-based flexible PDMS pressure sensors.

Sensors and Actuators A: Physical,

Vol. 285,

Issue. ,

p.

427.

Parameswaran, Chithra

and

Gupta, Dipti

2019.

Large area flexible pressure/strain sensors and arrays using nanomaterials and printing techniques.

Nano Convergence,

Vol. 6,

Issue. 1,

Male, Umashankar

and

Huh, Do Sung

2019.

Fabrication of robust honeycomb patterned porous films by thermochemical cross-linking of polyimide.

Polymer,

Vol. 178,

Issue. ,

p.

121597.

Preuksarattanawut, Charasphat

Nisaratanaporn, Ekkasit

and

Siralertmukul, Krisana

2019.

Highly ordered porous PLA films prepared by breath figure method.

Journal of Metals, Materials and Minerals,

Vol. 29,

Issue. 4,

Dai, Jianxun

Zhao, Hongran

Lin, Xiuzhu

Liu, Sen

Fei, Teng

and

Zhang, Tong

2020.

Humidity Sensors Based on 3D Porous Polyelectrolytes via Breath Figure Method.

Advanced Electronic Materials,

Vol. 6,

Issue. 1,

Li, Siming

Dong, Ke

Li, Ruiqing

Huang, Xiayan

Chen, Tianjiao

and

Xiao, Xueliang

2020.

Capacitive pressure sensor inlaid a porous dielectric layer of superelastic polydimethylsiloxane in conductive fabrics for detection of human motions.

Sensors and Actuators A: Physical,

Vol. 312,

Issue. ,

p.

112106.

Dombrovsky, Leonid A.

Frenkel, Mark

Legchenkova, Irina

and

Bormashenko, Edward

2020.

Effect of thermal properties of a substrate on formation of self-arranged surface structures on evaporated polymer films.

International Journal of Heat and Mass Transfer,

Vol. 158,

Issue. ,

p.

120053.

Kwak, Yeunjun

Jo, Eunhwan

Kang, Yunsung

and

Kim, Jongbaeg

2020.

Highly Transparent Porous Polydimethylsiloxane with Micro-Size Pores Using Water and Isopropanol Mixture.

p.

287.

Chen, Ying

Zhang, Yingchao

Liang, Ziwei

Cao, Yu

Han, Zhiyuan

and

Feng, Xue

2020.

Flexible inorganic bioelectronics.

npj Flexible Electronics,

Vol. 4,

Issue. 1,